-

Hot Off the Press! A Bestseller is Born: Suan Houseware Ships Trendsetting Color Changing Cups to Major US Amazon Seller

-

Make Your Mark: Custom Logo Silicone Wine Glass – The Ultimate Party Essential!

-

Shatter the Status Quo: Meet the 12oz Silicone Wine Glass That Elevates Every Sip

-

SuanHouse Delivers Premium Glass Spice Jar Sets, Reinforcing Global Supply Capabilities

-

SuanHouse Delivers Custom Silicone Collapsible Cups to Brazilian Law Firm, Highlighting Versatile Branding Solutions

-

Bamboo Lid Glass Spice Jars: A Comprehensive Product and Market Analysis

-

Electric heating tape is used to melt snow at airports

Airport snowmelt is key to maintaining normal airport operations in winter. Under extreme weather conditions, snow-covered runways and aprons can pose huge safety risks for aircraft taking off and landing, seriously endangering the safety of passengers, crew and airport staff. Traditional methods include manual removal and heating equipment, but these methods are inefficient and time-consuming. With the development of science and technology, electric heating tape, as an efficient and energy-saving snow melting equipment, has been widely used in the field of airport snow melting. This article will introduce the principles, advantages and application of electric heating tapes in airport snow melting.

-

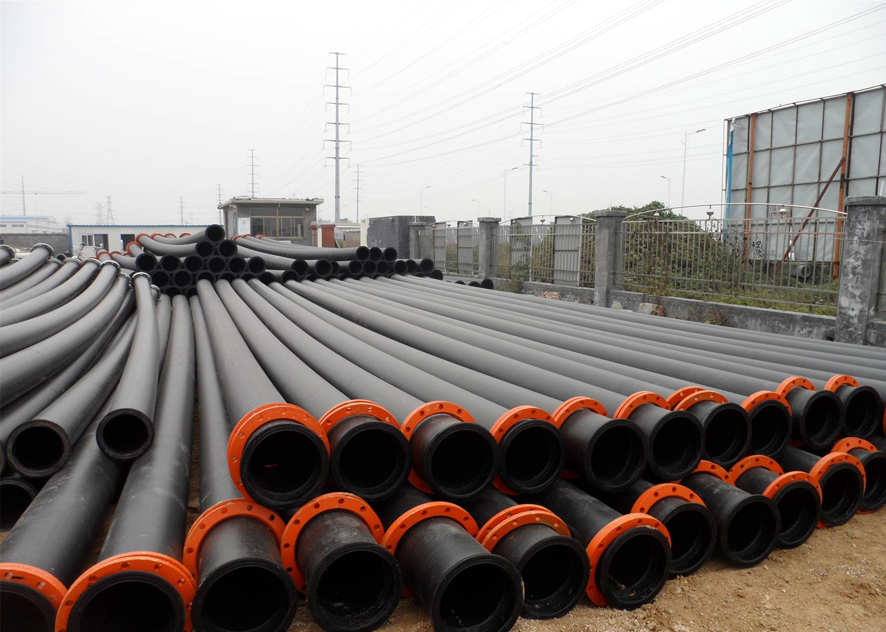

Features of heating tape for plastic pipes

Heating tape is an electric heating device that can be used for insulation and anti-freezing of various pipes. Its working principle is to supplement the heat loss by generating heat from the electric heating wire to maintain the temperature of the material in the pipeline and ensure the normal operation of the pipeline. Plastic pipes are one of the common applications for heating tapes. The following introduces the characteristics of heating tape used in plastic pipes.

-

Electric heating tape grid heating mat

Electric heating tape grid heating mat is a new type of heating product. It combines the advantages of electric heating tape and grid heating mat, providing people with an efficient, environmentally friendly and comfortable heating method.

-

Application of electric heating tape in oil transportation pipelines

With the continuous development and application of science and technology, electric heating tape has become an indispensable part of oil transportation pipelines. The application of electric heating tape not only improves the transportation efficiency of pipelines, but also provides strong support for the development of the petroleum industry.

-

Advantages of electric heat tracing in winter insulation and anti-condensation of chemical plant pipelines

From November 1st to 3rd, the temperature in the central and eastern parts of Northwest China, Inner Mongolia, North China, Northeast China, Huanghuai, Jianghan and other places will drop by 4~8℃, and the temperature in central Inner Mongolia, central Northeast China and other places will drop by more than 10℃. The above-mentioned areas are accompanied by winds of magnitude 4 to 6, with gusts of magnitude 8-9 in central and western Inner Mongolia and other places; some areas in central and western Inner Mongolia, western Gansu, northern Shaanxi and other places have blowing sand or dust weather; the Altay region of Xinjiang, eastern Inner Mongolia, and Heilongjiang Moderate to heavy snowfall, localized blizzards or heavy blizzards occurred in some areas in the central and western regions.

-

Electric heating is used to prevent freezing of different water tanks

As winter approaches, the temperature gradually drops, and water tanks are one of the indispensable equipment in various industrial and civil fields. However, in low-temperature environments, water tanks are prone to problems such as freezing and cracking, which affects normal use. In order to solve this problem, electric heating technology came into being. The following discusses the application of electric heat tracing in antifreezing water tanks in different scenarios.

-

Electric heating tape is used for heating concentrated alkali pipelines

In the fields of petroleum, chemical industry, electric power and other fields, heated pipelines are often needed to meet process requirements. Among them, the heating of concentrated alkali pipelines is a relatively special requirement. Because concentrated alkali is highly corrosive, traditional heating methods cannot meet its needs. As a new type of pipeline heating method, electric heating tape has the advantages of safety, energy saving, environmental protection, etc., making it an ideal choice for heating concentrated alkali pipelines.

-

The role of heating tape in power plant flue gas desulfurization

With the development of society and the improvement of environmental awareness, power plant flue gas desulfurization technology has attracted more and more attention. As an effective thermal insulation material, heating tape plays an important role in power plant flue gas desulfurization. The following introduces the role of heating tape in power plant flue gas desulfurization.

-

Application of electric heat tracing in petroleum field

With the continuous advancement of science and technology, electric heating technology is increasingly used in the petroleum field. Electric heating technology is a modern technology that uses electrical energy to convert into heat energy to insulate, anti-freeze, anti-corrosion, anti-scale and other treatments for pipelines and equipment. The following is a detailed introduction to the application of electric heat tracing in the petroleum field.

-

Electric Heating Cable: An Essential Solution for Industrial Pipeline Applications

Electric heating cable is a versatile and indispensable solution for maintaining optimal temperatures in industrial pipelines. With its ability to provide precise and uniform heat distribution, this technology plays a crucial role in various industries, including oil and gas, chemical processing, food and beverage, and many others.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba