-

SuanSports National Day Holiday Notice & A Message of Unity Through Sports

-

Suan Sports Showcases Customization Excellence with Innovative Foldable Fiberglass Soccer Goal

-

Suan Sports Demonstrates Custom Manufacturing Prowess with Innovative Foldable Soccer Goal

-

Introduction of polar fleece fabric

-

Horse Fluffer Comb Becomes an Essential Tool in Modern Horse Care

-

Collapsible Animal Traps Offer Humane and Convenient Wildlife Control

-

Glittering Badges

The glittering badges can be customized with different images and colors, creating various styles. According to the guest's design, the glitter is available on a single color, multi-color mixed and irised color. So do the sizes and shapes of colored glitter, they are available for selection according to the designs.

-

Flag Lapel Pins

Flag lapel pins are the perfect way to take your country sign with you wherever you go. A reminder close to your heart represents where you come from. The popular flag lapel pins could be attached to your suit coat, cap, shirt, collar, bags, rucksacks and jacket by a butterfly clasp. As well as you could collect all kinds of flag lapel pins to represent where you have visited.

-

UV Printing On Soft Enamel

In the past, printing patterns could only be printed on the surface of new enamel badges and medals and keyrings etc, but since we have a new printing machine, printing on the surface of soft enamel badges or keyrings etc has become a reality.

-

Elegant Mens Cufflinks

Mens cufflinks are items of male jewelry that are used in dressy shirts in lieu of buttons on the sleeves. A relatively innovation in male attire, mens cufflinks are still in vogue for formal wear, and require the dress shirt made with French cuffs.

-

Metal Medals for Competitions

Medals are certificates given to the winners of various competitions. They are usually made of metal. In many sports competitions, metal medals are usually in gold, silver and bronze colors for the first, second and third place, respectively.

-

Multitudinous Badges

Our factory can make multitudinous badges of different materials and processes, such as metal badges, PVC badges, embroidered badges and so on.

-

Print Pin Is Also A Good Choice

The production of print pin is different from the enamel pin. It is full board printing, followed by die cutting, soldering and epoxy dropping. It has advantages in production time as well When designs of pin badges are hard to show all the details on designated sizes by stamping or die casting and enamel coloring, we suggest to present the designs by printing. The great advantage of print pin is that they retain all the details.

-

From(facebook): National Aviation Academy

Inward extensions from the field frame of an electric motor or generator around which the field coils are mounted. The pole shoes are fastened to the field frame to form a very low reluctance path for the lines of magnetic flux.

-

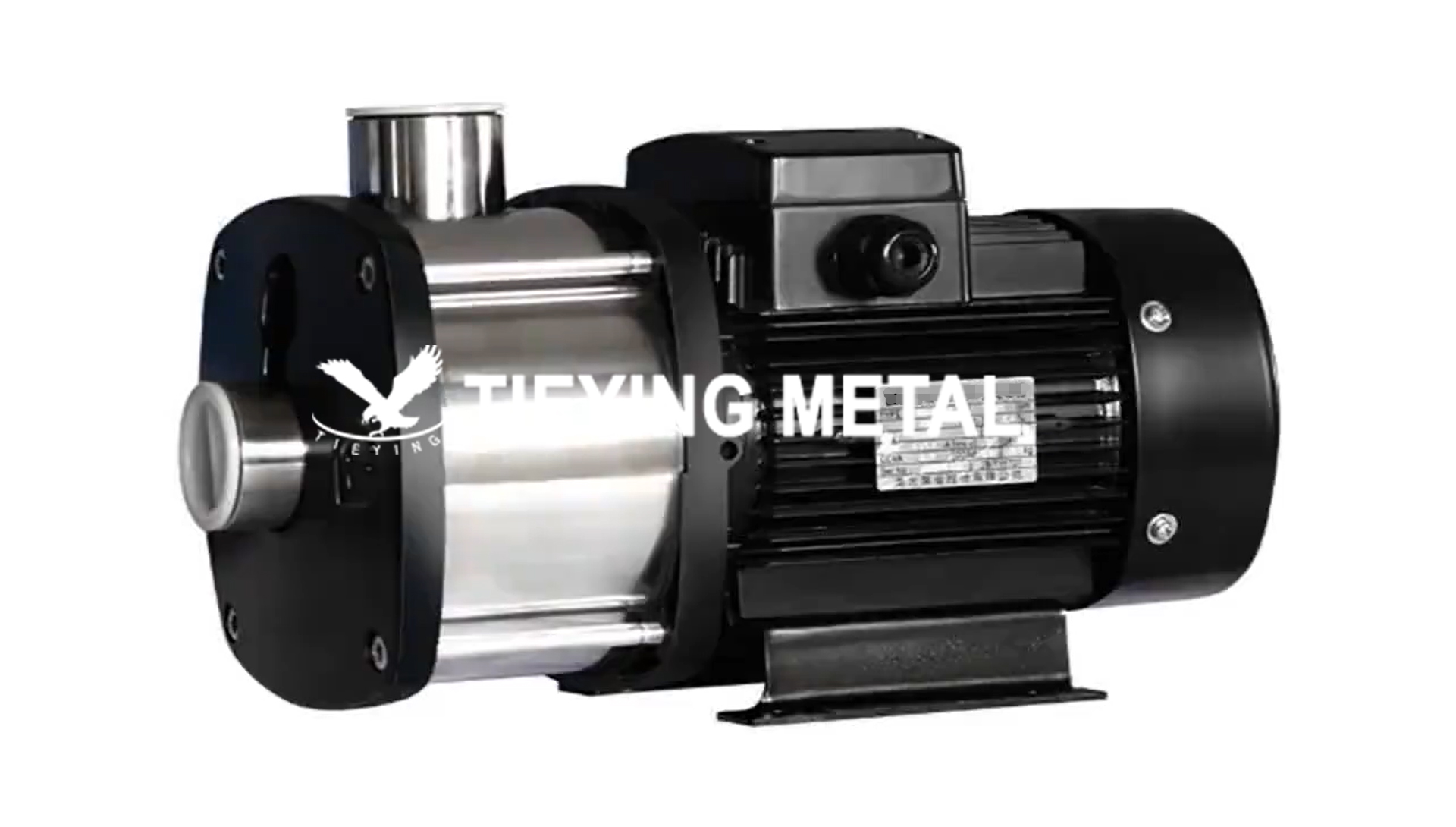

Oil Pump Motor Pole Shoe

Oil pump motor An improved specific motor that drives an oil pump. The oil pump motor includes the motor body, front end cover, and output transmission shaft. A stepped hole is opened on the front end cover, and the output transmission is retracted into the front end cover, forming a hollow shaft.

-

What are the issues to pay attention to when using a bomb cleaning machine

During the use process, some people may find that there are some problems with the ammunition cleaning machine, and the reasons for these problems are mostly caused by improper use.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba