The Hydro Jet Blasting Cleaning machine pump is a high-pressure operating equipment. It needs the general safety precaution process to ensure both the operator and machine safety.

Inspect Equipment

Inspect the condition of all parts before you use them. Do not use any item that is in suspect condition.

Check Pressure Ratings

All components in the Water blasting clean machine system must be properly rated for the intended operating pressure.

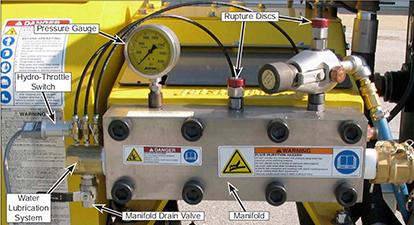

Rupture Discs

Installation of two rupture discs is necessary to protect the Hydro Jet Blasting Cleaning machine pump and operators. Generally, there are two Rupture disc ratings, 120% of operating pressure, and 140% of operating pressure.

Check Connections

Check the condition of the connection threads before you make any high pressure connection.

Tighten Connections

Properly tighten all high pressure connections. Hand-tighten pipe (NPT) fittings and then tighten with a wrench another 1-1/2 to 2 full revolutions.

Purge the Ultra-high Pressure hydro Jet cleaning pump System

Before attaching a nozzle to the control gun or tube cleaning lance, operate the pump at low speed to purge dirt and debris from the system. Dirt and debris can clog nozzle orifice and cause excessive system pressures.

Test the System

With the nozzle installed, operate the pump at low pressure to test the Water Jet cleaning machine pump system.

Slowly Increase Pressure

Visually inspect all fittings for leaks at 1000psi (69bar), and then again once the system reaches full pressure. Change the components when lead occurs.

Use the Minimum Pressure Required

Use the minimum pressure, do not exceed the operating pressure of the system’s lowest pressure-rated component.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba