In the water blasting industry cleaning application, surface preparation is an important job when you plan to do a painting on the material surface. It has to be handled correctly because it affects the service life, quality, and performance of the paint job.

Surface preparation has various methods depending on the repair and refurbishment scenarios and operational advantages, and here we mainly refer to two types of methods, the Water blasting and Sand blasting surface cleaning. And sand blasting surface cleaning is classified to dry sandblasting and wet sandblasting, given the dry sandblasting can make the dust cloud and other hazardous material harmful to the operator and the environment, it is required complete or partial closing down of the facility during blasting according to the safety operation instruction. Here we just compared water jet blasting and wet sandblasting.

Water jet blasting is an environment-friendly, safe, and money-saving way to clean and preserve various surfaces.

Water Jet blasting cleaning operation does not produce and release the toxic and hazardous dust and material to the environment and operator, and compared with chemical-base cleaning, no residues left behind, and no rinsing needed.

In Water Jet blasting, when propelled at a surface at sufficiently high velocity, water removes rust and old paint from the substrate, and also it effectively removes soluble salts.

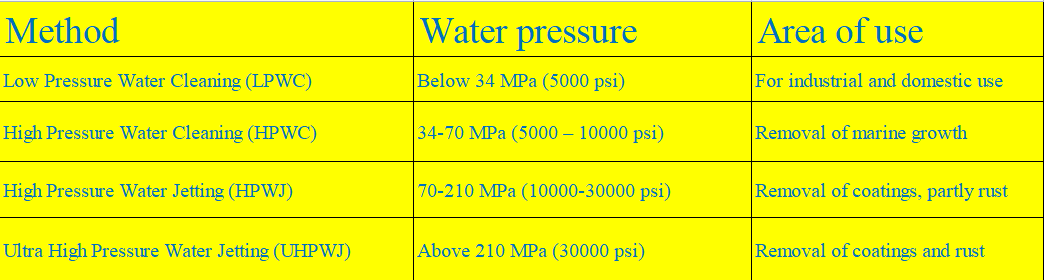

The water Jet blasting machine can change the pressure and use fan nozzles of different sizes depending on the job at hand, and the industry consensus is that the use of water pressurized at 70 MPa (=700 bar) or above constitutes water jetting. Below this pressure the operation is defined as water cleaning.

Scientific experiment test shows different pressure rates will have various surface cleaning effects, details as follows:

The Water Jet blasting ensures that being-prepared surface is free of chemicals and clean for other uses like coating and painting.

And the other water jet blasting cleaning features is that water jetting does not create a roughness profile in a metallic substrate.

Wet-sand blasting is conducted the surface preparation by means of water and compressed air as well as abrasive. It is with the water being either a propellant for the abrasive material or used for dust suppression.

This wet sandblasting cleaning of surface preparation provides both cleanliness and profile in one go.

Sandblasting has the advantage of cleaning a surface in a faster, better, and easier way than water blasting, and the pressure used in sandblasting can be changed depending on the type of operation carried out. But wet-sand blasting is for dust suppression. It may be insufficient to remove salts, and in most cases, it needs portable water to wash down and remove the abrasive, dust, dirt and salts.

Both Wet sandblasting and water Jet blasting cleaning have advantages and disadvantages, which way to choose depends on many parameters quite depend on the cleaning scenarios and specific requirements.

In the practice and application case, water blasting is more technically capable to cleaning surfaces, and without damaging the substrate’s original profile. It’s a cost-effective and eco-friendly method compared to comment abrasive blasting methods.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba