Dong Guan Zhuo Wei Air Purification Technology Co., Ltd.

Main Products:Filter, FFU air purification unit, Air shower, Cargo shower

130 Fuhai Road, Xiagang community, Chang’an town, Dongguan

+86-0769-81609661

sales@zhuoweiair.com

1. The Introduction of The Pharmaceutical Clean Room Air Shower

The Pharmaceutical Clean Room Air Shower is designed according to the form of the air shower room. The fan quickly blows the air out through the high-efficiency filter into clean air. The clean air passes through the stainless steel nozzle. After the nozzle is ejected, the airflow speed is as high as 20M/S. For the dust particles attached, the basic blowing time can be adjusted according to the manual switch.

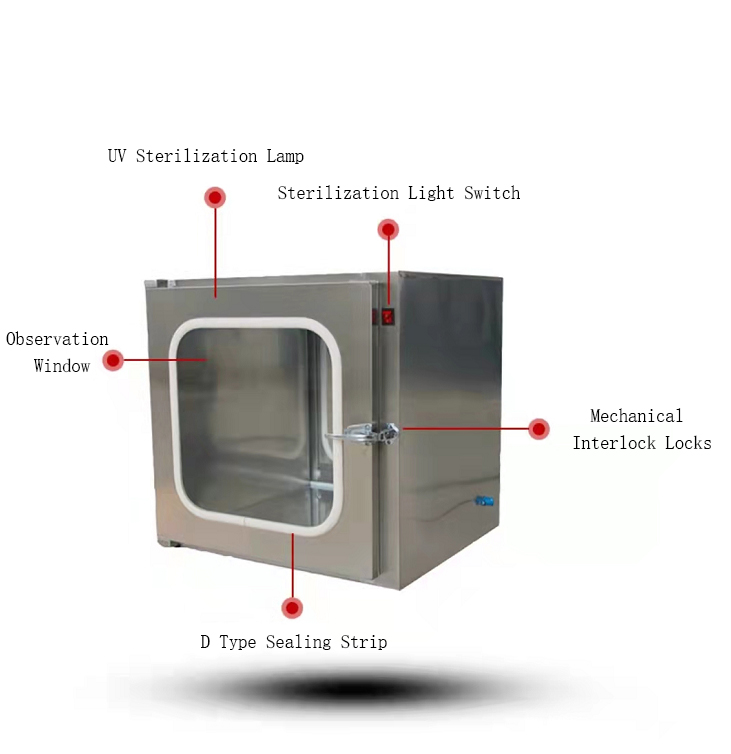

2. The Characteristics of The Pharmaceutical Clean Room Air Shower

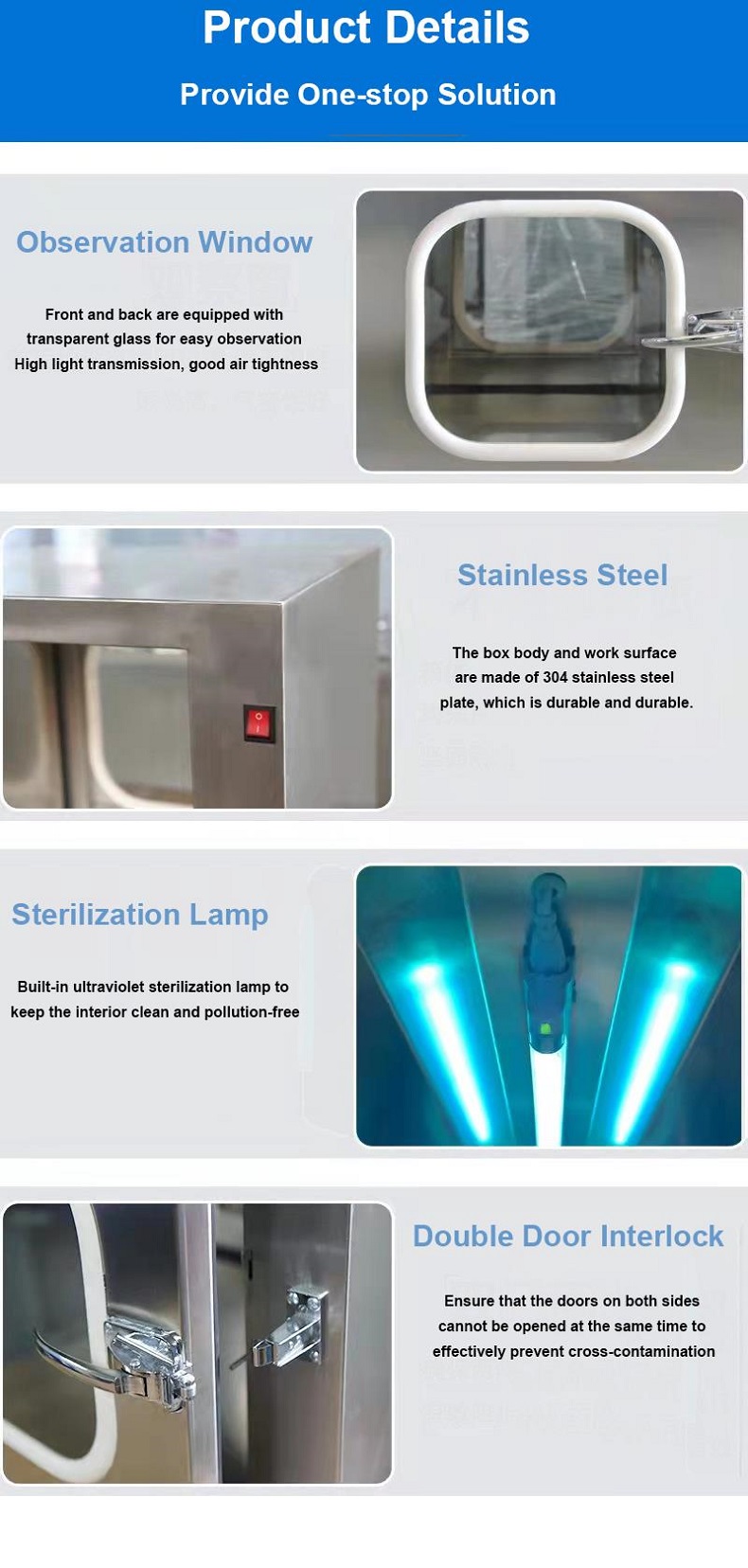

1). Electronic/mechanical interlock device, only one of the doors can be opened at the same time.

2). Air shower transfer window with 4 multi-angle adjustable nozzles, top blowing shower, with a large air volume, low noise fan, voltage: 380V, 50HZ, wind speed greater than 25m/s

3). Equipped with high-efficiency filter, the filtration efficiency is 99.99%@0.5um, to ensure the purification level

4). Fully automatic infrared induction blowing shower. When entering the clean area from the entrance, it will automatically blow the shower after infrared induction. When going out from the clean area, it will not blow through the transfer window to save energy.

5). Install a pick-up indicator on the entry and exit direction panels

3. The Feature of The Pharmaceutical Clean Room Air Shower

1). Optional UV germicidal lamp, walkie-talkie, roller

2). Mechanical interlock or electronic interlock, reliable performance

4. The Material of The Pharmaceutical Clean Room Air Shower

1). The outer wall is cold plate with white spray, the inner wall and top plate are stainless steel

2). The material of the box is all stainless steel, 201 and 304 stainless steel are optional

5. The Parameter of The Pharmaceutical Clean Room Air Shower

|

Model Name |

Transfer Window |

Transfer Window |

Air Shower Transfer Window |

|

Dimensions W*D*H(mm) |

760*660*700 |

960*860*900 |

950*660*1500 |

|

Internal dimensions W*D*H( mm) |

600*600*600 |

800*800*800 |

600*600*600 |

|

Box material |

The outer wall of the box is made of cold-rolled sheet/stainless steel, the surface is electrostatically sprayed, warm light white, and the inner wall is made of stainless steel. |

||

|

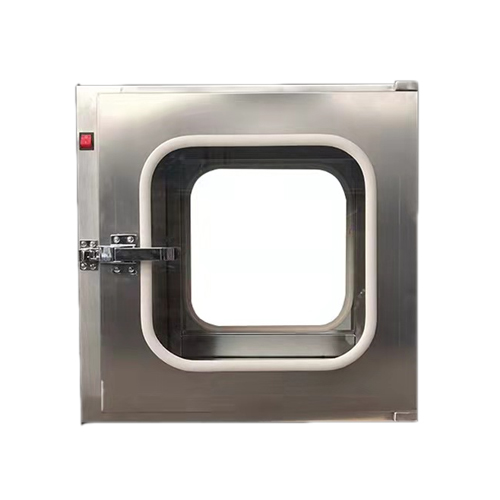

Door/Lock |

Half-glazed windows and doors, mechanically interlocked |

||

|

Nozzle |

4 |

||

|

Filter |

High efficiency filter (efficiency=99.99%) |

||

|

Power Consumption(Kw) |

0.37 |

||

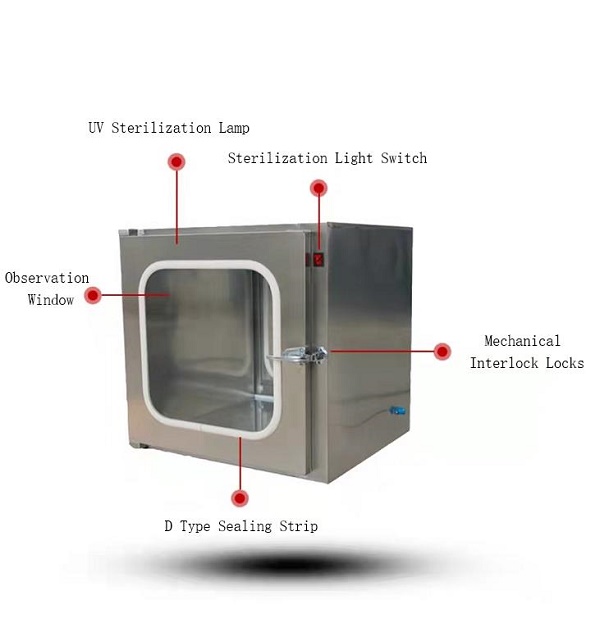

6. The Product Details of The Pharmaceutical Clean Room Air Shower

7. The Working Principles of The Pharmaceutical Clean Room Air Shower

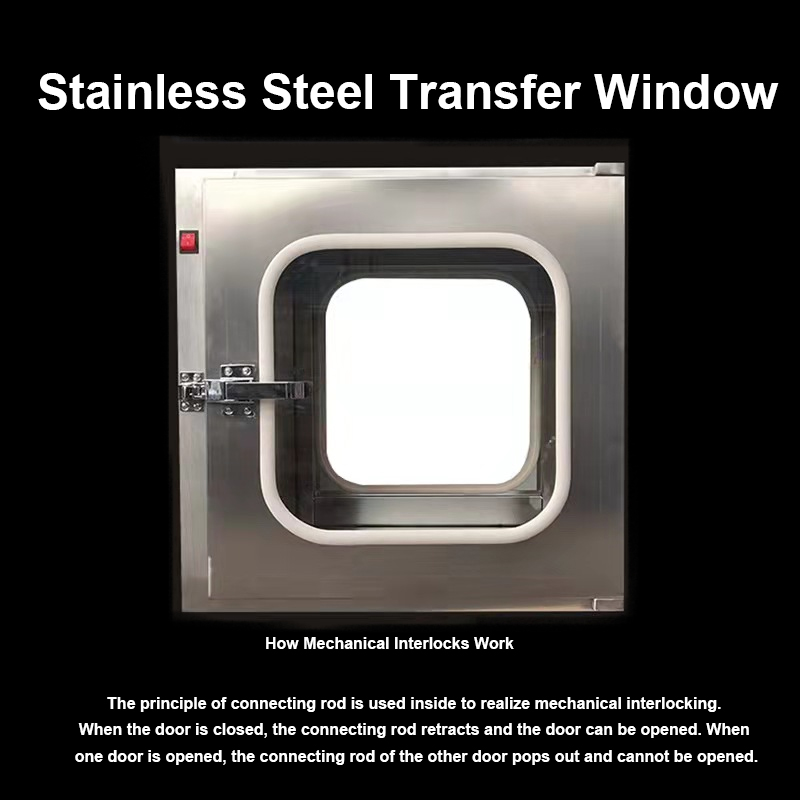

1). Mechanical interlocking device: The internal use of mechanical form to achieve interlocking, when one door is opened, the other door cannot be opened, and the other door must be closed before the other door can be opened.

2). Electronic interlocking device: the internal use of integrated circuits, electromagnetic locks, control panels, indicator lights, etc. to achieve interlocking, when one door is opened, the door indicator light of the other door does not light up, indicating that the door cannot be opened, At the same time, the electromagnetic lock action realizes interlocking. When the door is closed, the electromagnetic lock of the other door starts to work, and the indicator light will light up, indicating that the other door can be opened.

8. The Use of The Pharmaceutical Clean Room Air Shower

The transfer window is managed according to the cleanliness of the higher-level clean area connected to it. For example, the transfer window connected between the coding room and the filling room should be managed according to the requirements of the filling room. After get off work, the operator in the clean area is responsible for wiping the internal surfaces of the transfer window clean, and turning on the ultraviolet sterilization lamp for 30 minutes.

1). The material entering and leaving the clean area must be strictly separated from the flow channel, and the material enters and exits through the special channel of the production workshop.

2) When the materials enter, the raw and auxiliary materials will be unpacked by the person in charge of the preparation class or the surface will be cleaned, and then sent to the temporary storage room of raw materials and auxiliary materials in the workshop through the transfer window; and sent to the in-package room through the transfer window. The workshop integrator handles the material handover with the person in charge of the preparation and internal packaging processes.

3). When passing through the transfer window, the regulations of “one opening and one closing” for the inner and outer doors of the transfer window must be strictly implemented, and the two doors cannot be opened at the same time. Open the outer door and put the material in, then close the door first, then open the inner door to take out the material, close the door, and so on.

4). When the material in the clean area is sent out, the material should be transported to the relevant material intermediate station first, and the material should be moved out of the clean area according to the reverse procedure when the material entered.

5). All semi-finished products shipped from the clean area must be sent from the transfer window to the outer temporary storage room, and then transferred to the outer packaging room through the logistics channel.

6). Materials and wastes that are very likely to cause pollution should be transported from their dedicated transfer windows to non-clean areas.

7). After the material is in and out, the site of each clearing room or intermediate station and the sanitation of the transfer window should be cleaned up in time, the inner and outer access doors of the transfer window should be closed, and the cleaning and disinfection work should be done well.

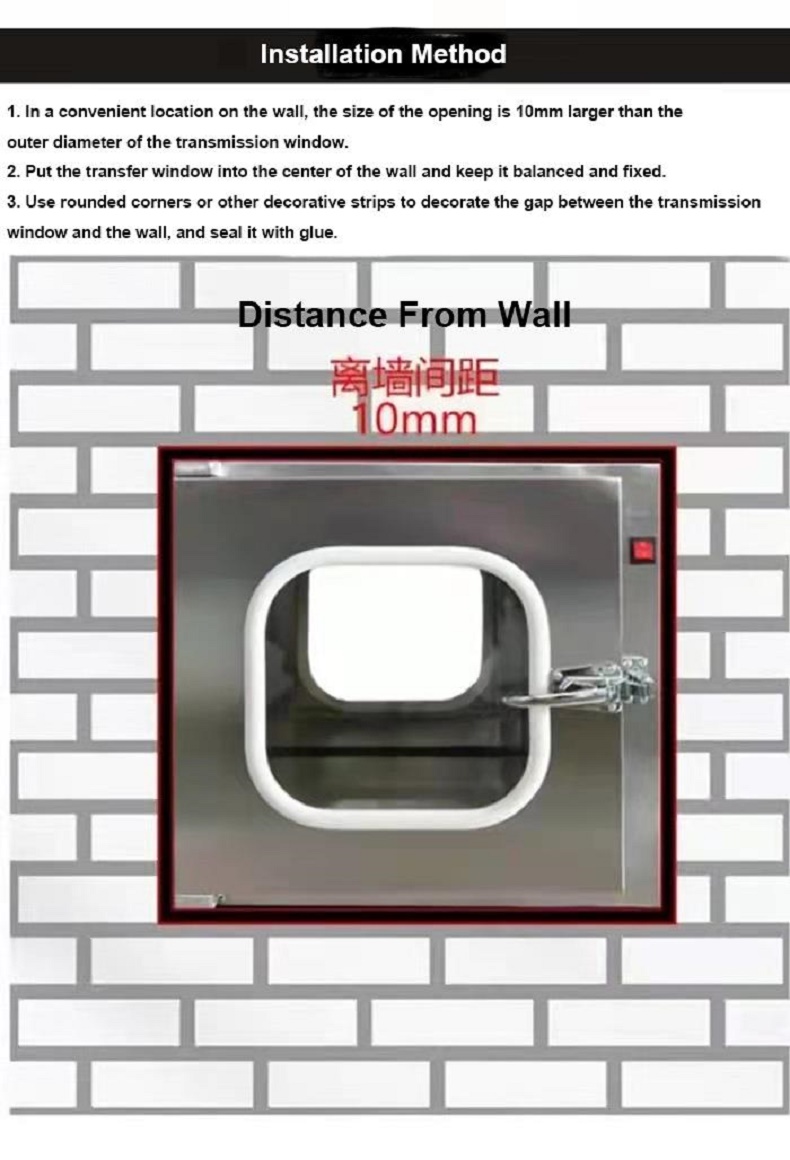

9. The Installation of The Pharmaceutical Clean Room Air Shower

Choose a convenient location on the wall, and then open the hole. The hole is generally about 10MM larger than the outer diameter of the transmission window. Put the transmission window into the wall, generally install it in the middle of the wall, keep it balanced and fixed, and decorate it with rounded corners or other decorative strips. The gap between the transmission window and the wall can be sealed and decorated with glue.

10. The Introduction of The Dong Guan Zhuo Wei Air Purification Technology Co., Ltd.

Dongguan Zhuowei Air Conditioning Electromechanical Equipment Co., Ltd. is a large-scale and productive air cleaning equipment manufacturer in South China. The company is located in Dongguan, the central city on the east bank of the Pearl River Delta. The factory covers an area of 2,000 square meters. The company was established in 2009. It is mainly engaged in the research and development, manufacture and sales of clean room purification equipment. , high-efficiency filters, high-efficiency air outlets, transfer windows, clean workbenches, clean sheds, FFU air purification units and other purification equipment, complete varieties, to undertake precision machinery, laboratories, biomedicine, food processing, electronics, circuit boards, optoelectronics, Supply and installation, debugging, testing and other one-stop services of purification equipment and consumables in the fields of optics, aerospace, circuit boards, and cosmetics.

Dongguan Zhuowei Air Conditioning Electromechanical Equipment Co., Ltd. produces in strict accordance with ISO9001 and ISO14001 product quality and environmental standards to ensure the required performance. Strict quality inspection procedures, from raw materials to finished product delivery, are strictly inspected to control product quality and ensure that products are qualified.

We always adhere to the corporate tenet of "survive by quality, seek market by reputation, seek development by technology, and seek benefit by management", adhering to the business philosophy of "creating first-class quality products and building Huaye's image", and constantly integrating product manufacturing and engineering and A professional and group business model integrating design and installation. We wholeheartedly provide you with high-efficiency, high-quality, high-rated construction management engineering services, and sincerely create a first-class clean space for you.

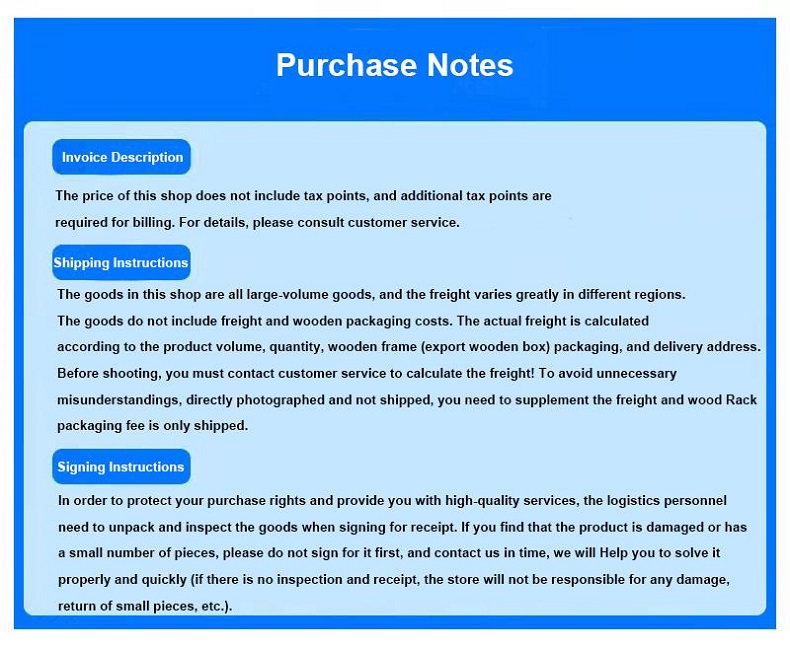

11. The Purchase Notes of The Pharmaceutical Clean Room Air Shower

12. FAQ:

Q1: What is you minimum order quantities?

A :Our MOQ is one set which can meet your sample requirement.

Q2: What is your leading time.

A :It’s based on your quantities and the sizes of the products.Generally it takes us 20 days for one container and 10 days for sample orders.

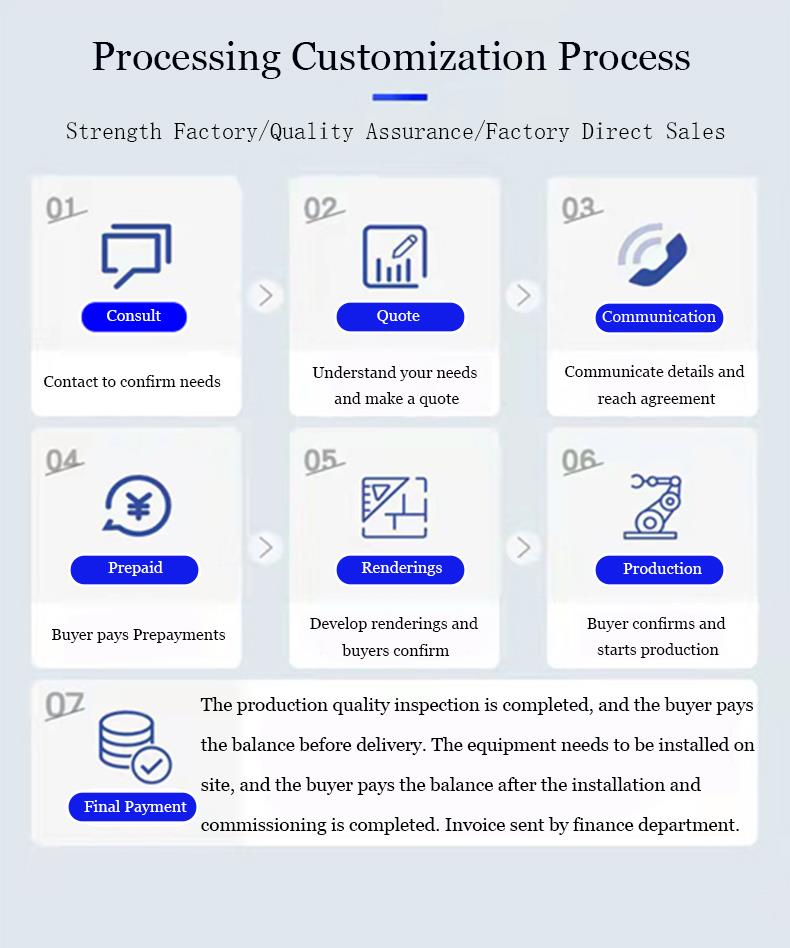

Q3: What is your payment terms?

A :30% by T/T as deposit, balance will be payed before delivery.

Q4: Do you accept OEM&ODM?

A: Yes

Q5: Why maxi?

1). 2 years warranty time guarantee

2). 24 hours to give you prompt and further information

3). Send invitation and arrange everything for you when you come to China

Hot tags: China, Air Shower Transfer Window, manufacturers, suppliers, factory, Manufacturers, Suppliers, Wholesale, Buy, Factory, Customized, In Stock, Bulk, High Quality, China, Made In China, Cheap, Low Price, Buy discount, Fashion, Newest, Advanced, Classy, Fancy, CE, ISO, Free Sample, Natural, High Dense, New Style, Beauty, Thick

Dong Guan Zhuo Wei Air Purification Technology Co., Ltd. was established in 2009. It is a high-tech company mainly engaged in R&D, manufacturing and sales of clean room purification equipment. The company specializes in the production of various types of air showers, cargo showers, initial, Medium and high-efficiency filters, high-efficiency air outlets, transfer windows, clean workbenches, clean sheds, FFU air purification units and other purification equipment, a complete range, to undertake precision machinery, laboratories, biomedicine, food processing, electronics, circuit boards, optoelectronics , optics, aerospace, circuit boards, cosmetics, purification equipment and supplies supply and installation, debugging, testing and other one-stop services.

We always adhere to the enterprise tenet of "survive by quality, seek market by reputation, seek development by technology, and seek benefit by management", adhering to the business philosophy of "creating first-class quality products and building Huaye's image", and constantly integrating product manufacturing and engineering and The professional and group-based business model integrating design and installation will wholeheartedly provide you with high-efficiency, high-quality, high-rated construction management engineering services, and sincerely create a first-class clean space for you.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba