JINAN SHENGBANG BEARING CO.,LTD.

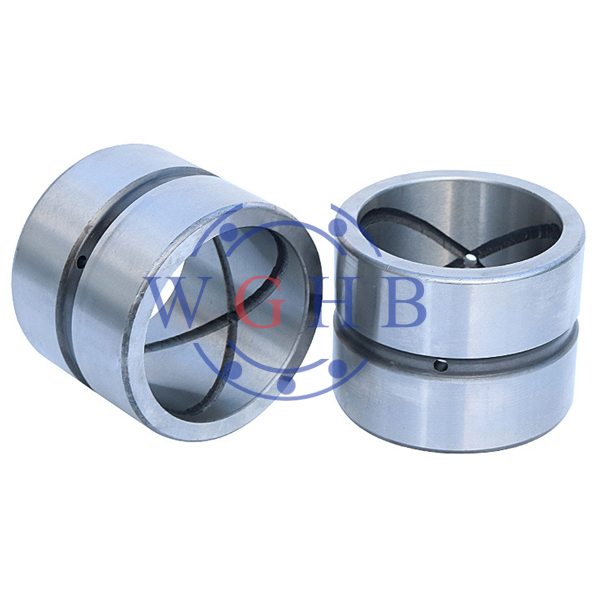

Main Products:Ball Bearing,Roller Bearing,Thrust bearing,Pillow block Bearing,Spherical Plain Bearing,Special Bearing

Jinan Economic Development Zone, Shandong Province, China

+86 13863522839

1017154081@qq.com

The bearing of the excavator is one of the important components of the excavator, which mainly plays the role of support and reducing friction, so that the various components of the excavator can operate smoothly. The bearings in different parts have different functions, such as the slewing bearing can allow the excavator to achieve the slewing action, while the drive wheel bearing ensures the normal rotation of the drive wheel.

The bearings of the excavator include: the bearing for the excavator to walk, the bearing for the excavator to rotate, the needle roller bearing of the excavator, the bearing of the excavator gearbox, the bearing of the excavator walking motor, the bearing for the excavator to walk and drive, the joint bearing of the excavator, the bearing for the excavator to rotate and support, and the British non-standard bearing used on the excavator.

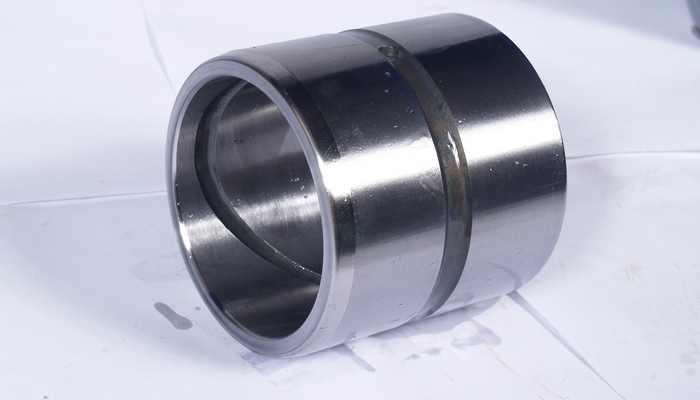

The large bearing of the excavator walking reducer, also known as the side reduction bearing or gearbox bearing, is mainly applied to the walking reducer of the crawler type excavator. The main categories are single-row angular contact ball bearings, double-row angular contact ball bearings, and tapered roller bearings.

When the excavator is working, the inner ring of the bearing rotates together with the shaft, and the outer ring is fixed on the body. The rolling elements roll between the inner and outer rings, converting the rotary motion of the shaft into smooth rotation, while bearing forces from all directions to ensure the normal operation of each component of the excavator. When selecting the bearing of the excavator, it is necessary to consider factors such as its bearing capacity, wear resistance, and sealing performance to ensure that it can operate stably in a harsh working environment.

The installation and disassembly methods of the bearing of the excavator should be determined according to the structure, size, and the fitting nature with the components of the bearing of the excavator. The pressure for installation and disassembly should be directly applied to the end face of the tight-fitting bearing retainer ring, and the pressure cannot be transmitted through the rolling elements of the bearing of the excavator, because this will cause indentations on the working surface of the bearing of the excavator, which will affect the normal operation of the bearing of the excavator, and even cause damage to the bearing of the excavator. The cage, seal ring, dust cover and other parts of the bearing of the excavator are easily deformed, and the pressure for installing or disassembling the bearing of the excavator cannot be applied to these parts.

Jinan Shengbang Bearing Co., Ltd. is a modern precision bearing manufacturer integrating R&D(research and development), production and sales. Our company has advanced production equipment, fully adopting advanced production technology and modern testing equipment to improve the precision performance of our products. The company promotes the"WGHB" brand, specializing in the production of deep groove ball bearings, taper roller bearings, spherical roller bearings, cylindrical roller bearings, pillow block bearings and other special bearings and non-standard bearings.

Our products with high precision and low noise, are widely used in metallurgy, mining,petroleum,chemical,coal, cement, paper,wind power, heavy machinery, port machinery and other industries. The company has independent import and export management rights. The products are sold all over the world, exported to more than fifty countries and regions such as South America,Western Europe, Southeast Asia, Central Asia, Africa and Australia.

The company always takes "solution, creation, value" as business philosophy, providing excellent bearing solutions for domestic and foreign customers. WGHB Bearings has passed ISO9001:2008 and ISO14001:2004. Through the implementation of strict quality standards, taking rigorous quality control measures to improve product quality and service quality, WGHB Bearings provides high quality products and services to consumers around the world.

Welcome all your OEM and ODM order. Your spefic purchase needs of selecting current product from our catalogue or seeking engineering assistance for your application will be directly submit to our customer service center, we will answer you ASAP.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba