Amsky Technology Co., Ltd.

Main Products:

Guangzhou Address: No.15 Hongwei Road, Industrial Park, Huangpu District, Guangzhou City<br>Hangzhou Address: No. 207 Dalingshan Road, Dongzhou Street, Fuyang District, Hangzhou City

86-13922233971

raymond@amsky.cc

|

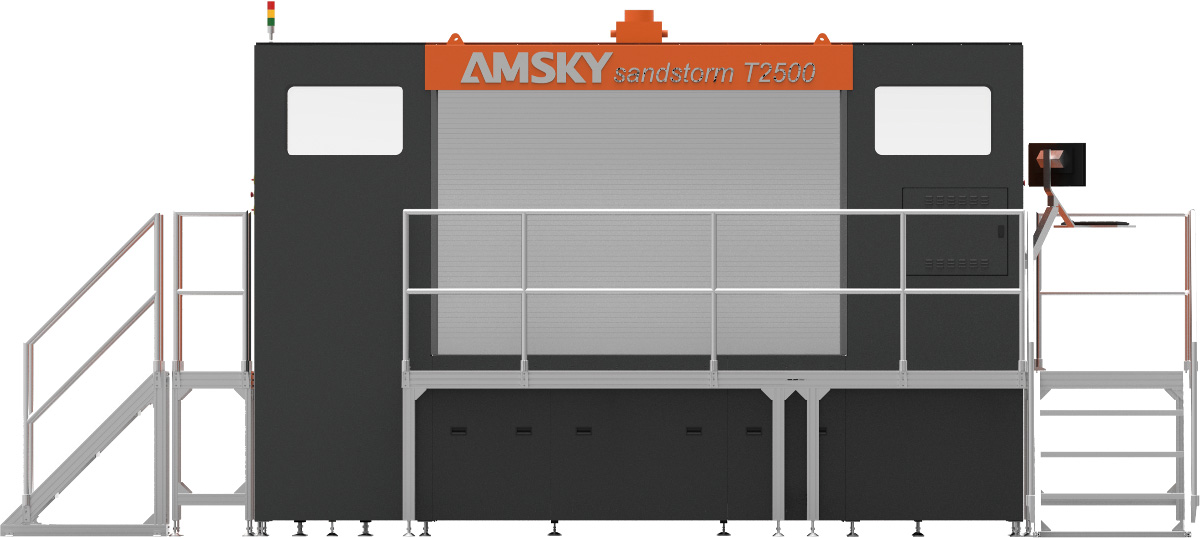

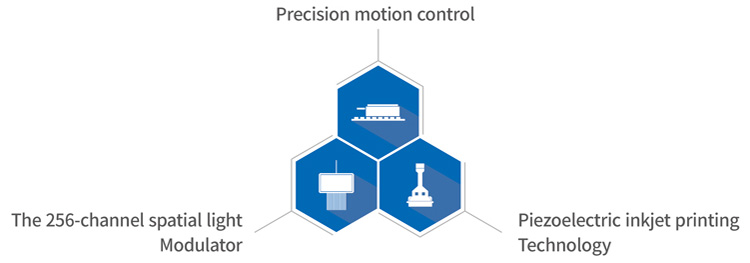

* Fast speed: Phenolic Resin: 32s / layer; Furan Resin: 27s / layer. * Use Amsky self- developed patented piezoelectric ink jet head for 3D printing. * With rail and trolley, this makes the job station moving around easily along the rail within the workshop thus fitting easily for the workflow layout together with the equipment of sand cleaning and other equipment. |

Technical specifications

| Build size |

2500x1000x800 mm (L x W x H) |

| Material | Furan resin or phenolic resin, curing agent, raw sand |

| Layer thickness | 0.2 - 0.5 mm |

| Resolution | 400-800 dpi |

| Build accuracy | ≤ 300 mm ±0.3 mm; > 300 mm ±0.1% (max) |

| Build speed | Phenolic Resin: 32 sec per layer;Furan Resin: 27 sec per layer |

|

Number of Job box |

Standard dual job boxes, individual drive, non-stop printing of job. |

|

Material loading method |

Automatic sand treatment + mixing of old and new sand in any proportion . |

| Structure form |

Structure frame + Linear motor + rail trolley + Sand cleaning and mold taking station |

| Noise | <60 db |

|

Mainframe size |

7880x4150x3600 mm (L x W x H) |

|

Full set layout |

1460x9300x4500 mm (L x W x H) |

| Net weight |

Main machine (including two job boxes): 5 Ton; Sand treatment center: 2.7 Ton, 14 Ton in total. |

| Environment |

Operating Temperature: 22-38℃, Humidity:55% |

MEMS Cleaning Room

Inkjet Print - head Cleaning Room

Establish PKU-AMSKY joint innovation lab of Intelligent equipment with PEKING University

Establish the doctor station with Zhejiang University

Cooperate with school of software of Beijing

Institute of Technology in the special R & D project Cooperate with Hebei University of Technology in 3D printing

Cooperate with Zhejiang University of Technology in 3D printing

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba