Xiangtan Lufeng Machinery Co., Ltd

Main Products:rotary furance ,ingot casting machine , electrolysis machine system

Building B6, Accelerator Park, No. 18 Gaoxin Road, Xiangtan, Hunan Province, China

+86-17773276726

layla@xtlfjx.com

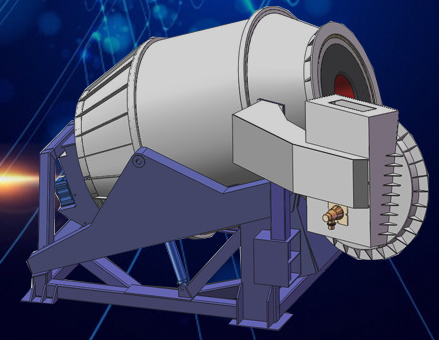

1. Product Introduction of Tilting rotary furnace

Impure WEE, Lead scrap, copper scraps, anode scraps, adaptable to different raw materials.

The furnace lining is composed of refractory layer, thermal insulation layer and thermal insulation layer. The furnace is made of high-strength one-time molding casting materials. The furnace is equipped with a fire stop ring, which can prolong the flame residence time, improve the melting speed and reduce energy consumption. The furnace has the characteristics of high performance, air tightness, high strength and long service life. The insulation layer and insulating layer are ceramic fiber materials. The furnace has the advantages of fast temperature rise, good heat preservation and low energy consumption.

The combustion system consists of a fan, a solenoid valve, an igniter, and a flame monitor. Connect the burner to the power supply and the burner will work.

2. Product Parameter (Specification) of Tilting rotary furnace

|

No. |

Furnace capacity (Effective volume m3) |

|

1 |

0.75 |

|

2 |

1.5 |

|

3 |

2 |

|

4 |

2.5 |

|

5 |

3.75 |

|

6 |

5 |

3. Product Feature And Application of Tilting rotary furnace

1) Adaptable to different raw materials, solid or liquid;

2) Convenient feeding type, even distribution of materials, fast melting speed;

3) Good heat transmission and high heat efficiency, with reasonable hearth structure and titling & shaking function;

4) High mechanization degree with same tube for reduction gas and oxidation gas by switching valves;

5) Good oxygen diffusion in copper liquid and efficient oxidized degree of perfect titling angle;

6) Minimum black smoke pollution as natural gas is used;

7) Flexible matting between copper liquid discharging process and casting process, furnace stays as same position to avoid “Run-copper” during casting failure;

8) Completely automatic operation, high operational efficiency, convenient for maintenance, and has long service life.

4. Product Details of Tilting rotary furnace

Horizontal fixed axis: metal and slag pouring from central.

Details include:

Refractory Material of Chrome-Magnesium basis;

Air-fuel burner or Oxy-fuel burner or Heavy oil burner;

Feeding door opening through local control panel and through remote control;

Door operation system with hydraulic unit;

Rotation system 0 - 1 rpm with variable speed driver (by VFD).

5. Product Qualification of Tilting rotary furnace

The Tilting rotary furnace is made of heat-resistant boiler steel, which can meet the working environment of high temperature.

6. Deliver, Shipping And Serving of Tilting rotary furnace

Tilting rotary furnace with Secure binding.We can provide FOB Shanghai / Qingdao / Shenzhen / Guangzhou and many other ports. China Lufeng Machinery factory is a professional Tilting rotary furnace manufacturer and supplier, wholesale High Quality Newest Tilting rotary furnace Made In China, choose Lufeng Machinery factory, our Advanced Tilting rotary furnace is low quotation, easy-maintainable, latest selling and CE certified.

7. FAQ

Q: How many years have your company made this kind of equipment?

RE: Since 2010.

Q: Do you have detailed and professional installation manual?

RE: We provide detailed installation, operation and maintenance instructions.

Q: Are you a trading company or a manufacturer?

RE: We are directly design and manufacturing supplier.

Q: Can you can design the equipment according to our size?

RE: sure, We provide non-standard designed and manufactured equipment.

Q: How many staff abroad you sent to install the equipment?

RE: Provide 2-3 engineers to guide installation and commissioning. 1-2 mechanical engineers, 1 Automation Engineer.

Q: How many days you need to install the equipment?

RE: The equipment specifications and quantities of each project are different, and the normal single unit lasts about 30 days.

Xiangtan Lufeng Machinery Co., Ltd. was established in 2010 and is located in the Industrial Park of Hunan Xiangtan High-tech Zone. Through more than 10 years of precipitation and development, Lufeng company has made many achievements in the design and manufacture of high-quality copper&lead&zinc smelting equipment.

Today, Lufeng has become one of the best manufacturers of high-quality smelting equipment in China and abroad, such as copper&lead smelting furnace, linear ingot casting machine, disc ingot casting machine, lead pot refining system, lead-acid battery crushing and sorting system, copper&lead&zinc electrolysis system, etc.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba