Features

(1) 4N2X series: 4N25, 4N26, 4N27, 4N28;4N3X series: 4N35, 4N36, 4N37, 4N38

-

High isolation voltage between input and output (Viso=5000 V rms)

-

Creepage distance >7.62 mm

-

Operating temperature up to +115°C

-

Compact dual-in-line package

-

ESD pass HBM 8000V/MM 2000V

-

Safety approval

UL approved(No.E323844)

VDE approved(No.40029733)

CQC approved (No.CQC19001231480 )

-

In compliance with RoHS, REACH standards.

-

MSL Class Ⅰ

Instructions

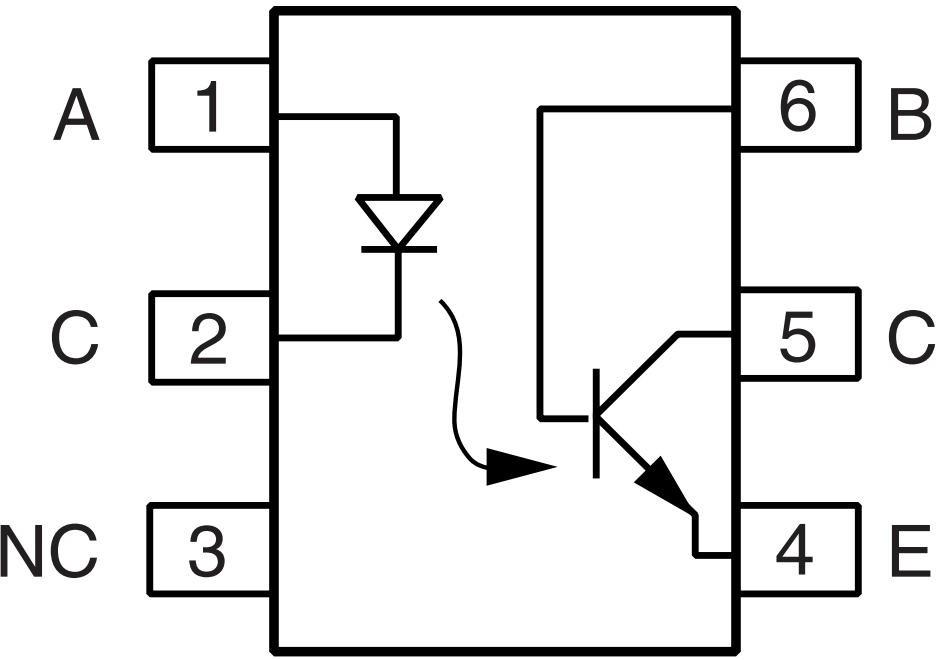

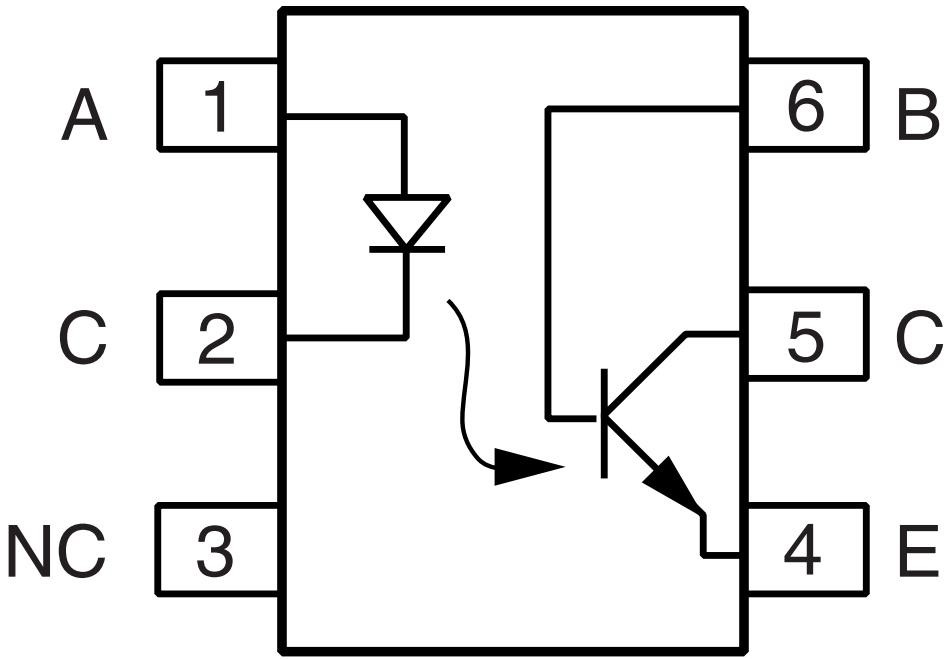

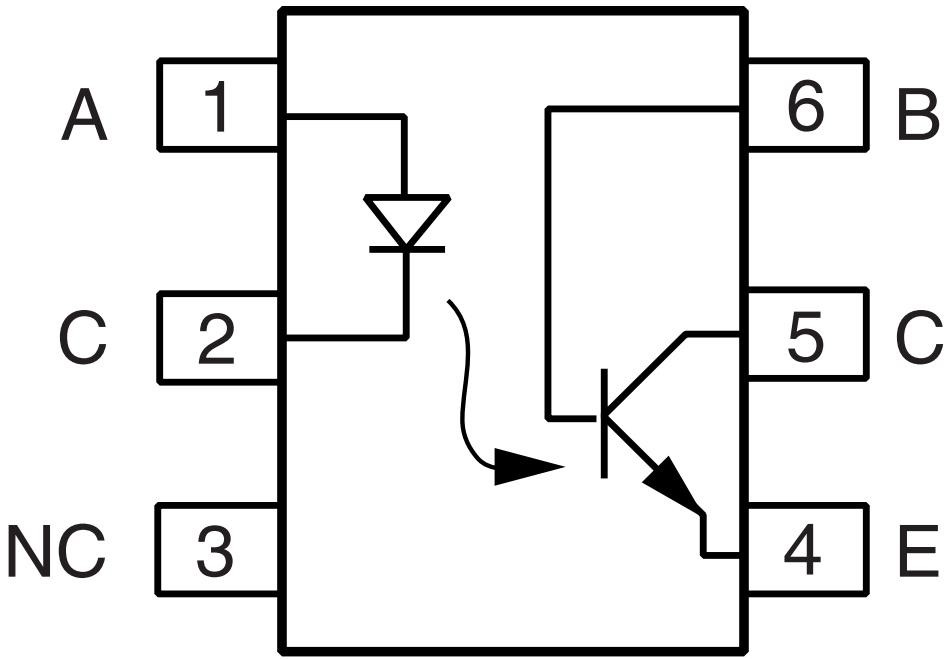

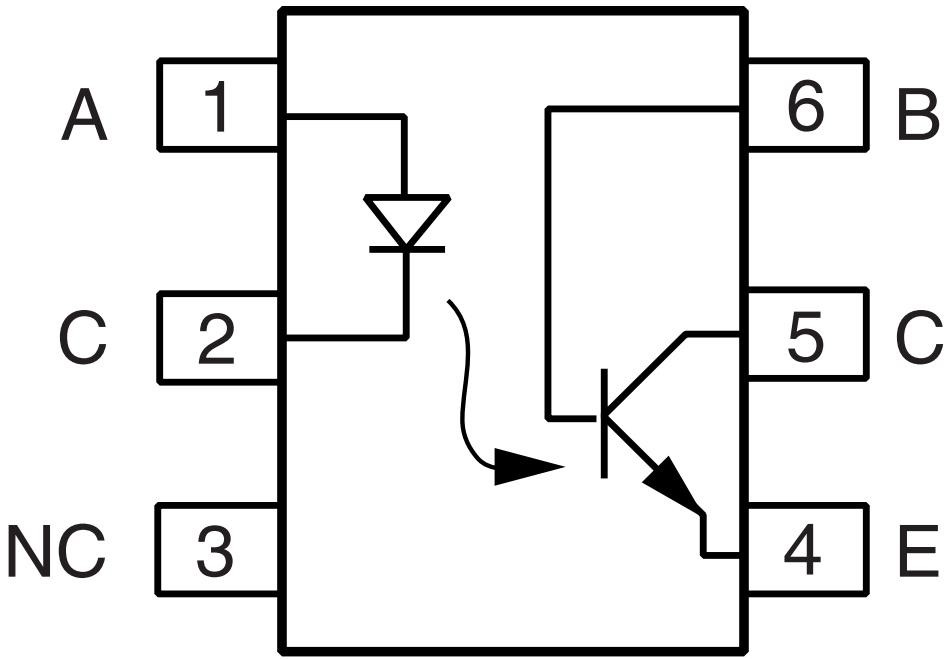

The 4N2X, 4N3X, series of devices each consist of an infrared emitting diode

optically coupled to a photo transistor.They are packaged in a 6-pin DIP package and available in wide-lead spacing and SMD option.

Application Range

-

Power supply regulators

-

Digital logic inputs

-

Microprocessor inputs

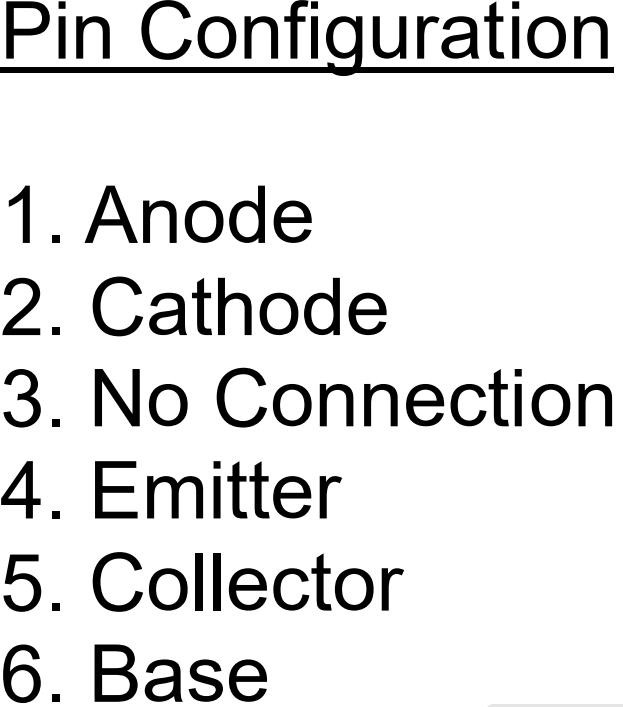

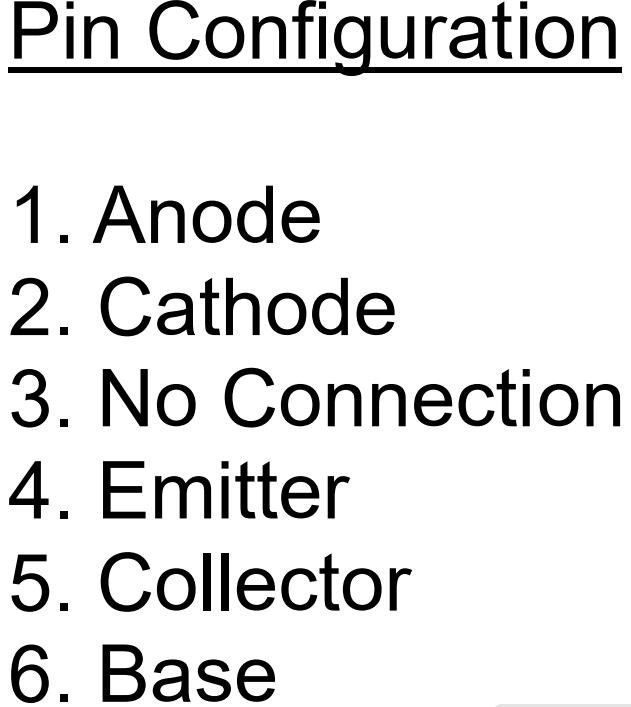

Functional Diagram

Max Absolute rated Value (Normal Temperature=25℃)

|

Parameter |

Symbol |

Rated Value |

Unit |

|

|

Input |

Forward Current |

IF |

60 |

mA |

|

Junction Temperature |

TJ |

125 |

℃ |

|

|

Reverse Voltage |

VR |

6 |

V |

|

|

Power dissipation (T A = 25°C) Derating factor (above 100°C) |

PD |

100 |

mW |

|

|

3.8 |

mW/°C |

|||

|

Output |

Collector-emitter Voltage |

VCEO |

80 |

V |

|

Collector-Base voltage |

VCBO |

80 |

||

|

Emitter-Collector voltage |

VECO |

7 |

||

|

Emitter-Base voltage |

VEBO |

7 |

||

|

Power dissipation (T A = 25°C) Derating factor (above 100°C) |

PC |

150 |

mW |

|

|

9.0 |

mW/°C |

|||

|

Total Consume Power |

Ptot |

200 |

mW |

|

|

*1 Insulation Voltage |

Viso |

5000 |

Vrms |

|

|

Working Temperature |

Topr |

-55 to + 115 |

℃ |

|

|

Deposit Temperature |

TSTG |

-55 to + 150 |

||

|

*2 Soldering Temperature |

TSOL |

260 |

||

*1. AC Test, 1 minute, humidity = 40~60% Insulation test method as below:

- Short circuit both terminals of photocoupler.

- No Current when testing insulation voltage.

- Adding sine wave voltage when testing

*2. soldering time is 10 seconds.

Opto-electronic Characteristics

|

Parameter |

Symbol |

Min |

Typ.* |

Max |

Unit |

Condition |

||

|

Input |

Forward Voltage |

VF |

--- |

1.2 |

1.5 |

V |

IF=10mA |

|

|

Reverse Current |

IR |

--- |

--- |

10 |

μA |

VR=6V |

||

|

Collector capacitance |

Cin |

--- |

30 |

--- |

pF |

V=0, f=1MHz |

||

|

Output |

Collector-Base dark current |

ICBO |

--- |

--- |

20 |

nA |

VCB=10V |

|

|

Collector to emitter Current |

4N2X |

ICEO |

--- |

--- |

50 |

nA |

VCE=10V, IF=0mA |

|

|

4N3X |

--- |

--- |

50 |

VCE= 60V, IF=0mA |

||||

|

Collector-Emitter attenuation Voltage |

BVCEO |

80 |

--- |

--- |

V |

IC=1mA |

||

|

Collector-Base breakdown voltage |

BVCBO |

80 |

IC=0.1mA |

|||||

|

Emitter-Collector attenuation Voltage |

BVECO |

7 |

--- |

--- |

V |

IE=0.1mA |

||

|

Emitter-Base breakdown voltage |

BVEBO |

7 |

IE=0.1mA |

|||||

|

Transforming Characteristics |

Current Transfer ratio |

4N35, 4N36,4N37 |

CTR |

100 |

--- |

--- |

% |

IF=10mA VCE=10V |

|

4N25, 4N26,4N38 |

20 |

--- |

--- |

|||||

|

4N27, 4N28 |

10 |

--- |

--- |

|||||

|

Collector and Emitter Saturation Voltage |

4N25, 4N26,4N27, 4N28 |

VCE(sat) |

--- |

--- |

0.5 |

V |

IF=50mA IC=2mA |

|

|

4N35, 4N36,4N37 |

--- |

--- |

0.3 |

IF=10mA, IC=0.5mA |

||||

|

4N38 |

--- |

--- |

1.0 |

IF=20mA, IC=4mA |

||||

|

Isolation resistance |

Riso |

1011 |

--- |

--- |

Ω |

DC500V 40~60%R.H. |

||

|

Floating Capacitance |

Cf |

--- |

0.2 |

--- |

pF |

V=0, f=1MHz |

||

|

Response Time |

tr |

--- |

3 |

10 |

μs |

VCC=10V, IC=10mA RL=100Ω |

||

|

Descend Time |

tf |

--- |

6 |

10 |

μs |

|||

-

Current Conversion Ratio = IC / IF × 100%

Order Information

Part Number

OR-4NXXU-Y-Z

Note

4NXX = Part Number, 4N25,4N26,4N27,4N28,4N35,4N36,4N37 or 4N38.

U = Lead form option (S, M or None)

Y = Tape and reel option (TA,TA1 or none).

Z = ‘V’ code for VDE safety (This options is not necessary).

* VDE Code can be selected.

|

Option |

Description |

Packing quantity |

|

None |

Standard DIP-6 |

66 units per tube |

|

M |

Wide lead bend (0.4 inch spacing) |

66 units per tube |

|

S(TA) |

Surface mount lead form (low profile) + TA tape & reel option |

1000 units per reel |

|

S(TA1) |

Surface mount lead form (low profile) + TA1 tape & reel option |

1000 units per reel |

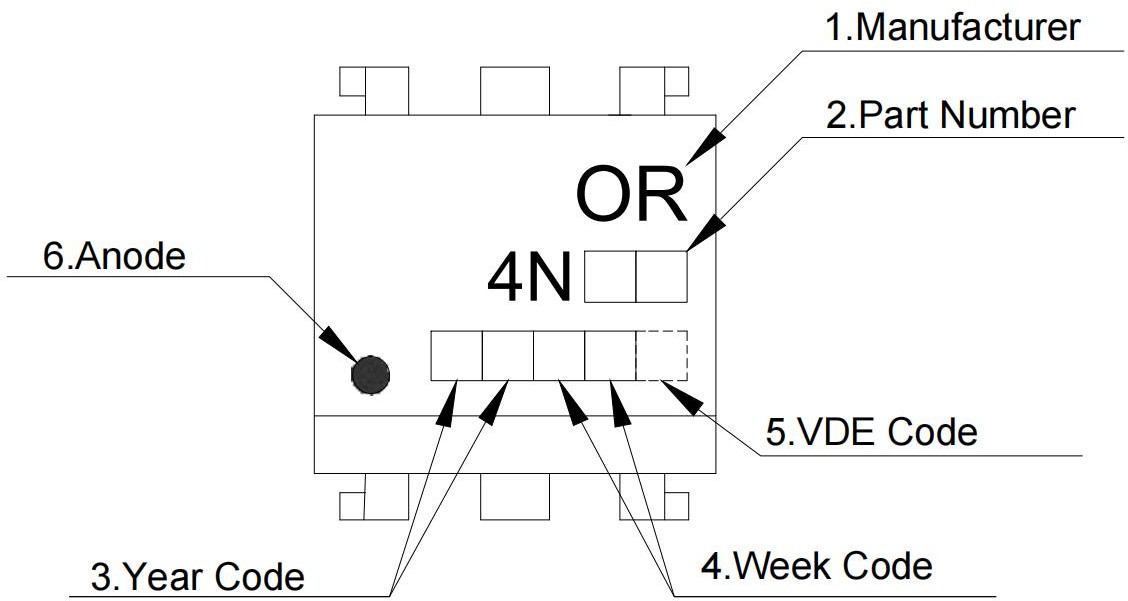

Naming Rule

1. Manufacturer : ORIENT.

2. Part Number : 4N25,4N26,4N27,4N28,4N35,4N36,4N37 or 4N38.

-

Year Code

: '21' means '2021' and so on.

: '21' means '2021' and so on. -

Week Code

: 01 means the first week, 02 means the second week and so on.

: 01 means the first week, 02 means the second week and so on. -

VDE Code

. (Optional)

. (Optional) -

Anode.

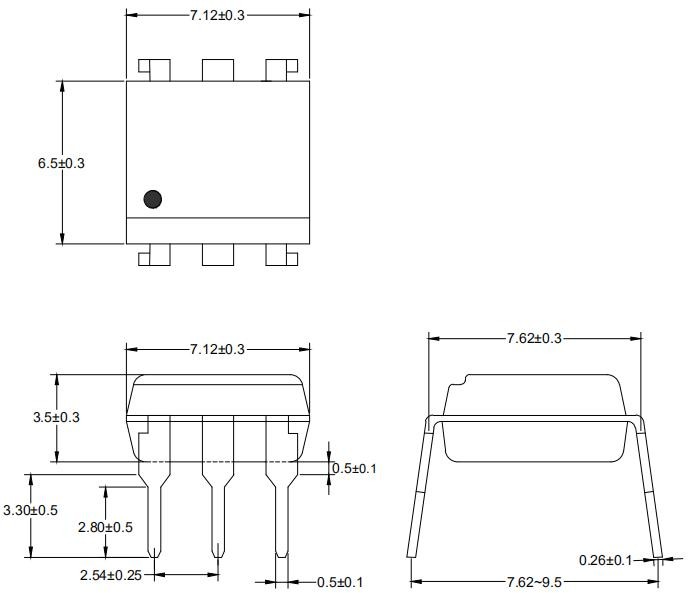

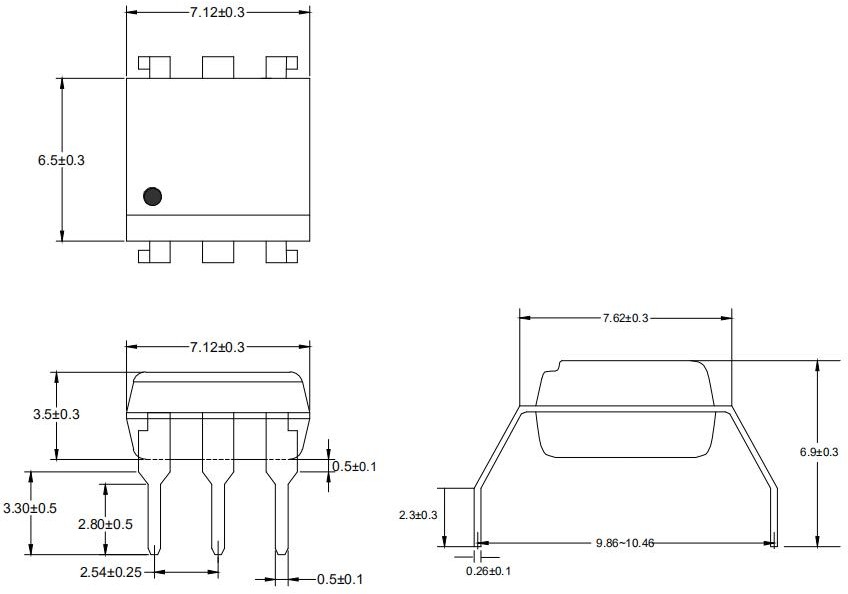

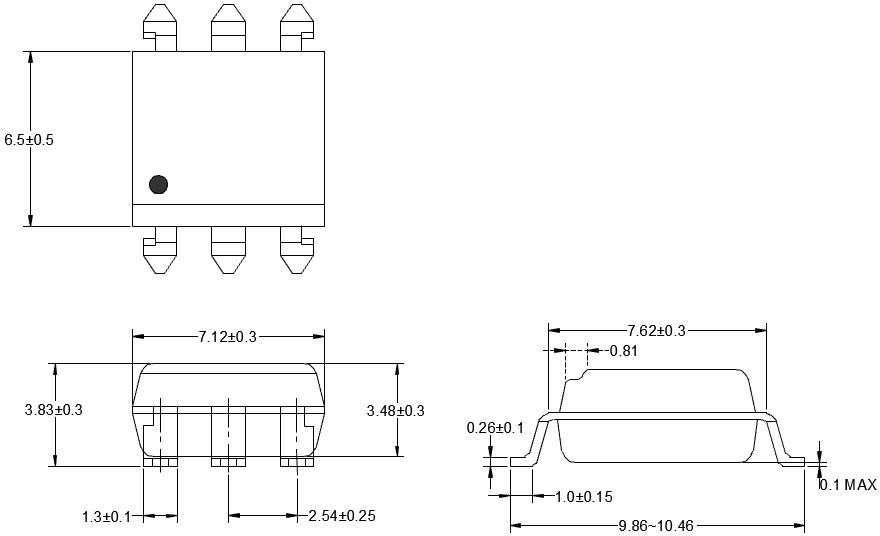

Outer Dimension

OR-4NXX

OR-4NXXM

OR-4NXXS

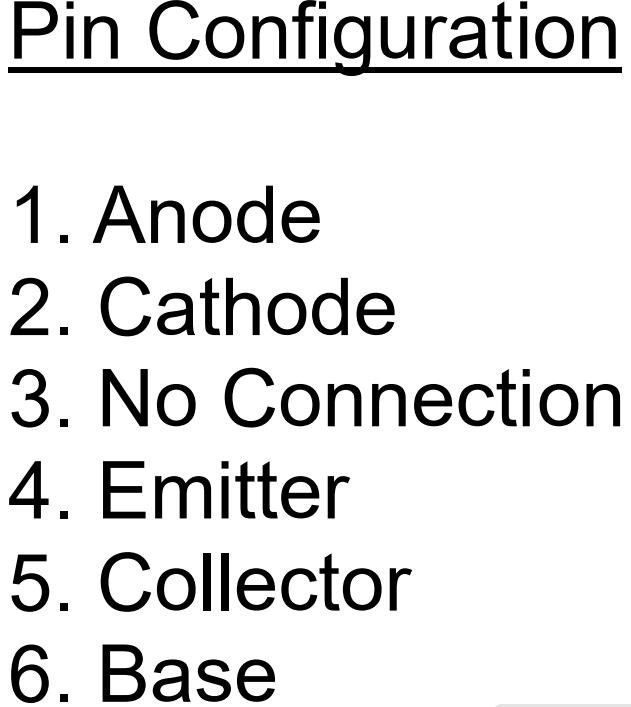

Recommended Foot Print Patterns (Mount Pad)

unit:mm

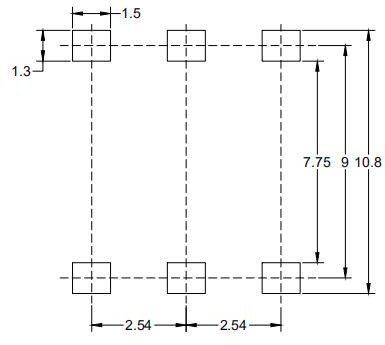

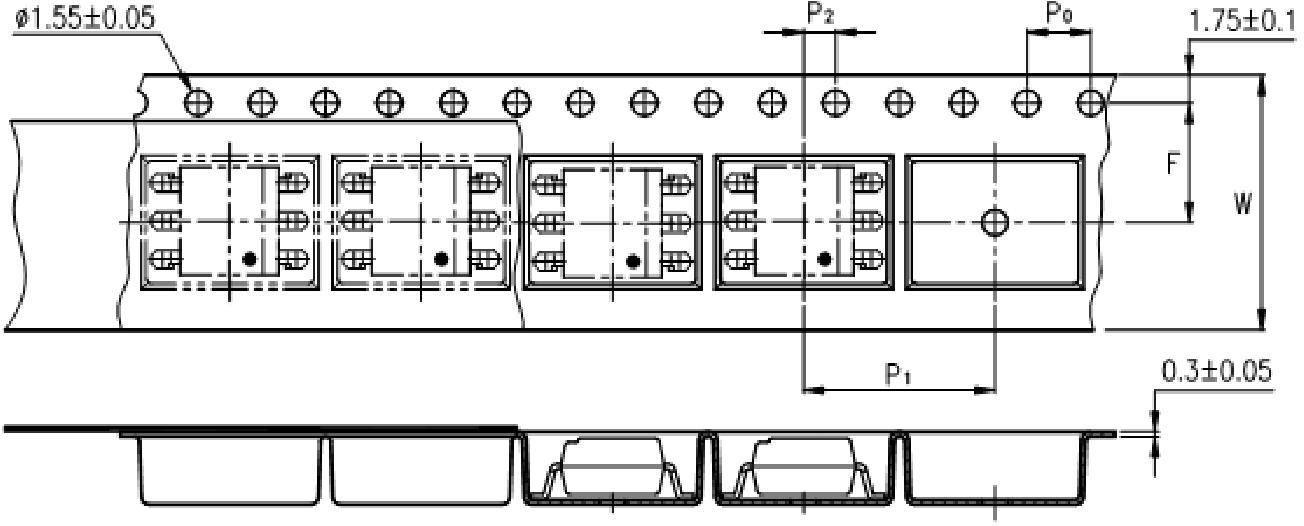

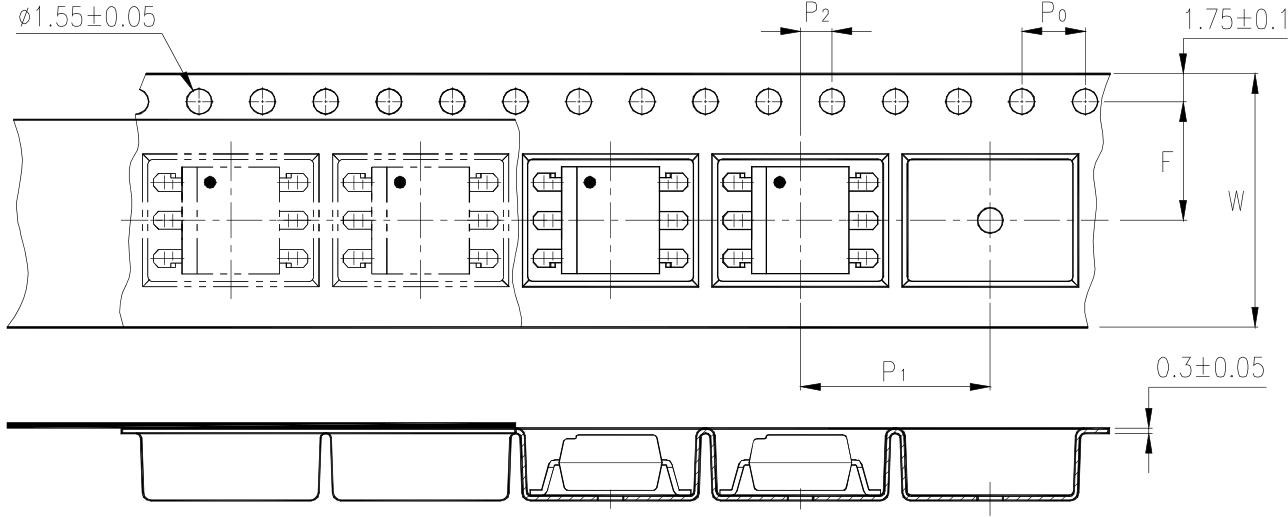

Taping Dimensions

OR-4NXXS-TA

OR-4NXXS-TA1

|

Description |

Symbol |

Dimension in mm(inch) |

|

Tape wide |

W |

16±0.3(0.63) |

|

Pitch of sprocket holes |

P0 |

4±0.1(0.15) |

|

Distance of compartment |

F |

7.5±0.1(0.295) |

|

P2 |

2±0.1(0.079) |

|

|

Distance of compartment to compartment |

P1 |

12±0.1(0.472) |

|

Package Type |

TA/TA1 |

|

Quantities(pcs) |

1000 |

Package Dimension

DIP/M type

|

Packing Information |

|

|

Packing type |

Tube |

|

Qty per Tube |

66pcs |

|

Small box (Inner) Dimension |

525*128*60mm |

|

Large box (Outer) Dimension |

545*290*335mm |

|

The Amount per Inner Box |

3,300pcs |

|

The Amount per Outer Box |

33,000pcs |

SOP type

|

Packing Information |

|

|

Packing type |

Reel type |

|

Tape Width |

16mm |

|

Qty per Reel |

1,000pcs |

|

Small box (inner) Dimension |

345*345*58.5mm |

|

Large box (Outer) Dimension |

620x360x360mm |

|

Max qty per small box |

2,000pcs |

|

Max qty per large box |

20,000pcs |

Packing Label Sample

Note:

-

Material Code :Product ID.

-

P/N :Contents with "Order Information" in the specification.

-

Lot No. :Product data.

-

D/C :Product weeks.

-

Quantity :Packaging quantity.

Reliability Test

-

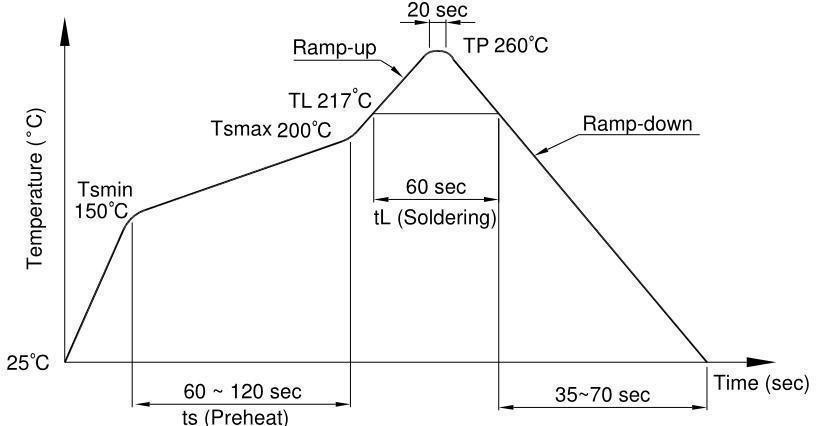

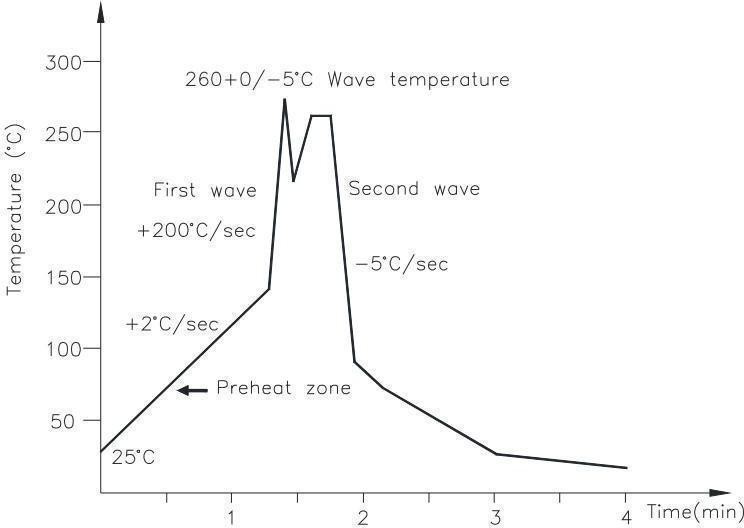

Temperature Profile Of Soldering

(1) IR Reflow soldering (JEDEC-STD-020C compliant)

One time soldering reflow is recommended within the condition of temperature and time profile shown below. Do not solder more than three times.

|

Profile item |

Conditions |

|

Preheat

- Time (min to max) (ts) |

150˚C 200˚C 90±30 sec |

|

Soldering zone - Temperature (TL ) - Time (t L ) |

217˚C 60 sec |

|

Peak Temperature |

260˚C |

|

Peak Temperature time |

20 sec |

|

Ramp-up rate |

3˚C / sec max. |

|

Ramp-down rate from peak temperature |

3~6˚C / sec |

|

Reflow times |

≤3 |

(2) Wave soldering (JEDEC22A111 compliant)

One time soldering is recommended within the condition of temperature.

|

Temperature Time |

260+0/-5˚C 10 sec |

|

Preheat temperature Preheat time |

25 to 140˚C 30 to 80 sec |

(3) Hand soldering by soldering iron

Allow single lead soldering in every single process. One time soldering is recommended.

Temperature

380+0/-5˚C

Time

3 sec max

Characteristics Curve

Shenzhen Orient Components Co., Ltd. is the China leading manufacturer of optocouplers with mass production of more than 400 parts, serving markets like Telecommunications, Electric Power, Home appliances, Automotive and Green Energy. We are customer orientedand strive to provide rapid response and long termvalue-added services to our customers.

Shenzhen Orient Components Co., Ltd. is a national high-tech enterprise specializing in R&D, manufacturing of optoelectronic chips and optocouplers. Orient has mastered the core technology of chips and has a complete IDM industrial chain. Orient's optocouplers and optoelectronic devices have developed into domestic high-end products, including 9 categories and more than 400 models: transistor, Schmidt trigger, thyristor optocoupler, high speed isolation optocoupler, PhotoMos SSR optocoupler, IGBT isolation optocoupler, current and voltage sensor, linear optocoupler and optoelectronic sensor. All of them provide sevices to communication, home appliances, vehicles, new energy and other industries, and basically match with European, American and Japanese optocouplers in application. Currently, the overall production and sales of Orient rank at the top in China. With the continuous expansion of production in the next five years, Orient strives for a well-known international optocoupler brand. In 2021, as the leading brand in the optocoupler industry, Orient was selected as one of the National ' Specialized and Innovative 11 enterprises.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba