Electric floor heating is a heating method that uses electric energy to heat the floor. It has the advantages of energy saving, environmental protection, comfort, intelligence, etc. The following are its top ten advantages:

Energy saving: Compared with traditional radiator heating, electric floor heating can achieve large-area heating using only electric energy, and has high energy efficiency.

Environmental protection: Electric floor heating does not require the use of liquefied gas, natural gas and other fuels used in traditional radiators, nor does it produce toxic and harmful gases and waste, and has no pollution to the environment.

Comfort: Electric floor heating heats the ground quickly, giving people a natural feeling of warmth and making people feel comfortable.

Intelligence: Electric floor heating can be automatically controlled, and the power can be automatically adjusted according to indoor temperature and user needs, achieving intelligent operation and management.

Stable temperature control: Electric floor heating uses high-efficiency heating materials such as graphene carbon ink processing and carbon fiber. It heats quickly and evenly, and has stable temperature control, which can meet the needs of different users.

Easy installation: Electric floor heating does not require laying keels. It only needs to lay graphene electric floor heating on the ground. Ceramic tiles or wooden floors can be laid on top. It is easy to install and has a short construction period.

Long service life: The heating material used in electric floor heating is mainly carbon. Carbon is the most stable element in the world, has a long life and is corrosion-resistant. The service life of graphene electric floor heating can reach more than 50 years.

Metering by household: Electric floor heating can realize metering by household. Users can independently control the temperature and power of each room, making it more flexible and economical to use.

Wide applicability: Electric floor heating can be used in various types of buildings, including residential, commercial, industrial, agricultural and other fields.

Safe and reliable: Electric floor heating equipment is installed below the ground, which will not cause harm to the human body or cause safety hazards such as leakage.

The top ten advantages of electric floor heating for decoration plans:

Improve the quality of the room: Electric floor heating heats the floor to make the indoor temperature evenly distributed, thereby improving the quality and taste of the indoor decoration.

Saving space: Compared with traditional radiator heating, electric floor heating does not need to occupy the floor area and can save floor space.

Improve the indoor environment: Electric floor heating heats the ground by radiation, does not pollute the indoor air, and can improve indoor air quality.

Eliminate dust: Compared with traditional radiator heating, electric floor heating can effectively eliminate indoor dust and improve indoor air quality.

Reduce maintenance costs: Electric floor heating does not have the maintenance problems of radiator heating. It only requires regular inspection and maintenance, which can save maintenance costs.

Save time: Compared with traditional radiator heating, electric floor heating heats the floor faster, which can save users time.

Beautiful and comfortable: Electric floor heating heats the floor without affecting the beauty and comfort of the room.

Reduce noise: Electric floor heating makes no noise when running, which can create a quiet living and working environment for users.

Easy to install: Electric floor heating can be installed in a short time without affecting the user's normal life and work.

Green and environmentally friendly: Electric floor heating uses clean energy - electric energy, which is a green and environmentally friendly heating method.

Ten major advantages of electric floor heating compared to gas wall-mounted boiler heating:

Higher safety: Electric floor heating will not cause safety problems such as leakage and fire, because its heating element is buried under the ground and will not cause harm to the human body. Gas wall-mounted boiler heating requires users to review the installation environment to prevent safety accidents such as leakage.

More convenient to use: Electric floor heating heats the ground faster, and users can turn it on and off at any time, which is very convenient. However, gas wall-hung boilers require users to heat water in advance and wait for a period of time before they can be used.

Better energy saving: Electric floor heating has a high energy efficiency ratio and does not consume a large amount of gas when used. It is more energy-saving than gas wall-mounted boilers for heating.

Better environmental protection: Electric floor heating will not produce toxic and harmful gases and waste, and will not cause pollution to the environment. Gas wall-mounted boilers for heating consume a large amount of gas and cause certain pollution to the environment.

Longer service life: The service life of the heating element of electric floor heating can reach more than 50 years, while the service life of gas wall-mounted boiler heating is generally about 20 years.

More accurate temperature adjustment: Electric floor heating can use a thermostat to adjust the temperature by time period and room, making it more intelligent. However, gas wall-mounted boilers require manual temperature adjustment for heating, which is not intelligent enough.

Wider scope of application: Electric floor heating is suitable for various types of buildings, including residential, commercial, industrial and other fields. Gas wall-mounted boilers are suitable for small-area places such as single-family villas.

Lower maintenance costs: Electric floor heating does not have the maintenance problems of radiator heating. It only requires regular inspection and maintenance, which can save maintenance costs. However, gas wall-mounted boiler heating requires regular replacement of boilers and pipes, and maintenance costs are high.

Lower installation costs: The installation of electric floor heating is simpler than gas wall-mounted boiler heating, because there is no need to lay keels and install radiators.

Longer service life: The service life of electric floor heating is longer than that of gas wall-mounted boiler heating, because its heating element has a long service life, which can save maintenance costs in the long term.

Installation process of electric floor heating:

Preparation work: Prepare the materials required for electric floor heating, including heating cables, accessories, insulation layers, reflective films, steel mesh, filling layers, etc. At the same time, heating cables, accessories and other tools need to be prepared according to professional drawings.

Cable detection: Before laying, each heating cable needs to be tested to ensure that there is no break or short circuit in the heating cable.

Laying of insulation layer: Before laying the insulation layer, the base layer needs to be processed and cleaned to ensure that the insulation board is laid on a flat and clean structural surface.

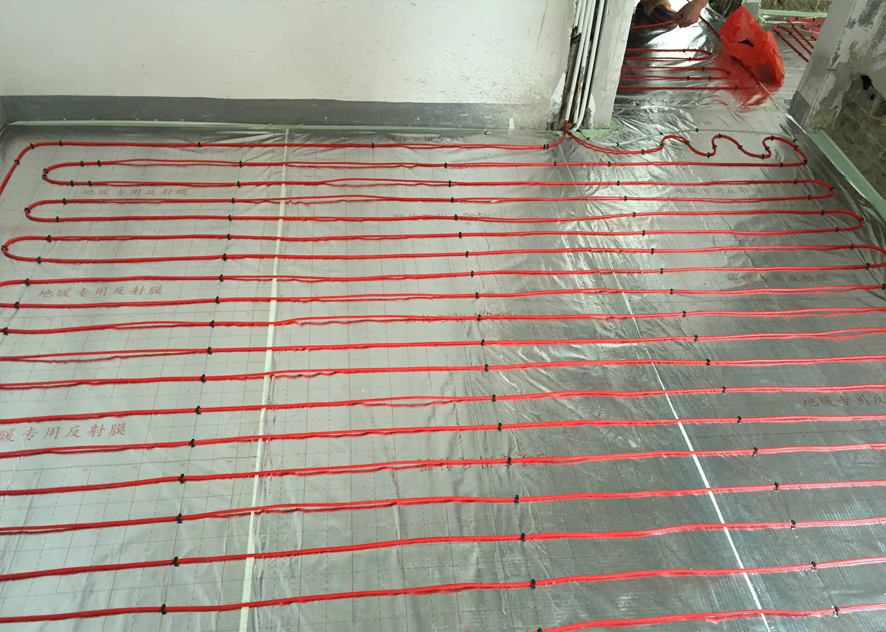

Laying of reflective film: Laying of floor heating reflective film can conduct heat evenly upwards and make the ground temperature uniform. It should be laid on extruded boards. The laying must be smooth and fixed with tape.

Laying steel wire mesh: Lay the steel wire mesh on the reflective film and fix it on the insulation board with clips. The main function of the steel wire mesh is to fix the heating cable and increase the strength of the cushion.

Laying heating cables: Lay the cables according to the design drawings. When laying the heating cables, strictly follow the drawings. Finally, connect the cold wire end to the thermostat.

Test again: After the laying is completed, the heating cable must be tested. The testing method is the same as the first time.

Install the thermostat: Put the floor heating probe through the pipe. The end of the pipe should be closed between the two cables and fixed with a clip or tie.

Filling layer construction: Before pouring the concrete filling layer, the base layer needs to be leveled and cleaned, and then the filling layer can be laid. When constructing the filling layer, attention should be paid to the absence of stones that are too large in size. The surface of the stones must be smooth and have no sharp corners, otherwise the heating cable may be easily damaged. Within 48 hours after the filling is completed, traders are strictly prohibited from stepping on it. After the filling layer is completed, the ground is strictly prohibited from being chipped or heavy-loaded.

Testing and debugging: After the electric floor heating is installed, testing and debugging are required to ensure the normal operation and use of the electric floor heating. For specific testing and debugging methods, please refer to relevant technical documents or consult professionals.

When considering the electrical load of electric floor heating and house power distribution, the following factors need to be considered:

The power and calorific value of electric floor heating: The power and calorific value of electric floor heating will be affected by many factors, such as area, room height, material, etc. When choosing electric floor heating, you need to determine the appropriate power and heat generation based on the actual needs of the room and the electrical load.

Power supply system: Electric floor heating requires the use of a power supply system, so the stability and reliability of the power supply system need to be considered. When selecting a power supply system, you need to choose reliable quality cables and electrical equipment, and you need to consider whether the capacity of the power supply system can meet the power demand for electric floor heating.

Voltage and electrical safety: The power supply system used by electric floor heating usually requires the introduction of power from the distribution room, so voltage and electrical safety issues need to be taken into consideration. When selecting power distribution equipment, it is necessary to select appropriate circuit breakers and switchgear to ensure the stability and safety of the power supply system.

Electricity and energy consumption: The electricity load of electric floor heating will be affected by factors such as room area and heating season. When designing and installing electric floor heating, electricity and energy consumption need to be taken into consideration to ensure reasonable electricity load and energy-saving effects.

Maintenance and management: Electric floor heating requires regular maintenance and management to ensure its normal operation and energy-saving effect. When choosing electric floor heating, you need to consider whether it is easy to maintain and manage, and whether there is relevant service and support.

To sum up, when considering the power load and house power distribution of electric floor heating, multiple factors need to be considered comprehensively to ensure reasonable power load and energy-saving effect.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba