In many industrial and civil fields, electric heat tracing insulation materials are widely used to maintain temperature stability in pipelines, equipment and containers. It is crucial to choose electric heating insulation materials suitable for different occasions, because it directly affects energy efficiency, safety and economy. The following introduces the selection of electric heating insulation materials in different occasions.

1. Industrial piping and equipment

In industrial environments, pipes and equipment often need to be kept within a certain temperature range to ensure normal production processes. For these applications, selecting electrical heat tracing insulation materials with high insulation properties is key. Commonly used materials include fiberglass, aluminum silicate, and rock wool. These materials have excellent thermal insulation properties and high temperature resistance, effectively reducing heat loss.

2. Tanks and Containers

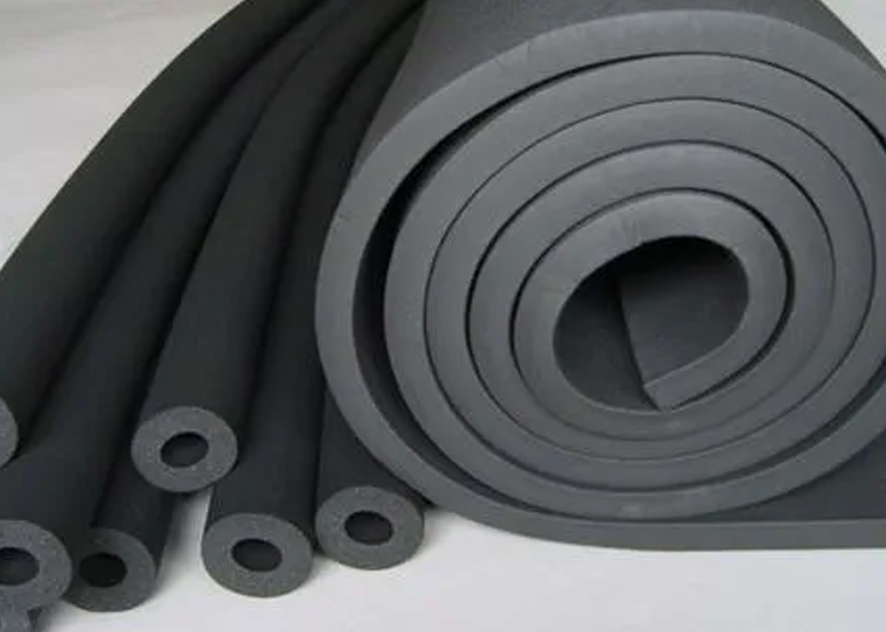

In tanks and containers that store liquids or gases, the selection of electric heating insulation materials should take into account the needs for moisture and corrosion protection. Generally speaking, using materials such as polyurethane foam, polyethylene foam, or rubber is a more suitable choice. These materials have good sealing properties, preventing moisture and gas penetration while providing good thermal insulation.

3. Outdoor pipes and equipment

For pipes and equipment exposed to the outdoor environment, electrically traced insulation needs to be UV-resistant, water-resistant and weather-resistant. In this case, it is recommended to use materials such as polyurethane rigid foam, extruded polystyrene (XPS) or high-density polyethylene (HDPE). These materials have high mechanical strength and weather resistance, allowing them to maintain stable insulation properties under harsh weather conditions.

4. Food and pharmaceutical industry

In the food and pharmaceutical industries, electric heat tracing insulation materials must meet strict hygiene standards. Therefore, it is crucial to choose non-toxic, odorless and pollution-free materials. Commonly used materials include polyurethane, polyethylene, and polypropylene. These materials have good chemical stability and corrosion resistance and are suitable for applications in contact with food and pharmaceuticals.

5. High temperature applications

In some high-temperature situations, such as industrial furnaces, ovens and heating equipment, it is necessary to choose electric heating insulation materials that can withstand high temperatures. Materials such as ceramic fiber, calcium silicate and fiberglass are ideal choices as they have excellent high temperature resistance and good insulation.

In short, several factors need to be considered when choosing electric heating insulation materials suitable for different occasions, including temperature range, moisture resistance, corrosion resistance, mechanical strength and hygienic standards. Depending on the specific needs and application environment, choosing the right electric heat tracing insulation materials can improve energy efficiency, ensure normal operation of equipment, and meet the safety and health requirements of related industries.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba