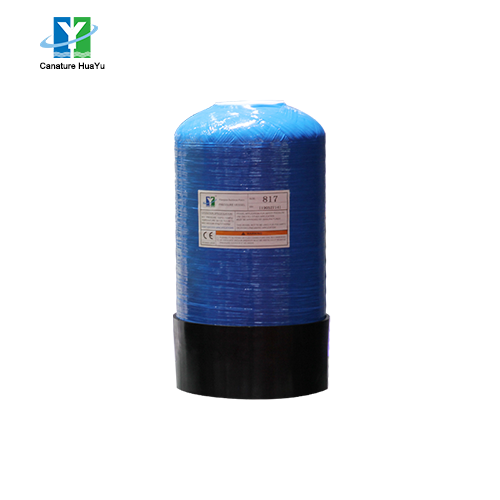

The glass fiber reinforced plastic FRP water tank is assembled by high-quality SMC water tank board. It is characterized by the use of food-grade resin, so the water quality is good, clean and pollution-free. The product has the characteristics of high strength, corrosion resistance, beautiful appearance, long service life, and convenient maintenance and management. If the FRP water tank is used for a long time, there may be water leakage. For this problem, we will now explain the reasons for water leakage in the FRP water tank and the solution.

1. Reasons for water leakage of FRP water tank

The reasons for the leakage of the FRP water tank are roughly as follows:

(1) Insufficient resin content;

(2) The elongation of the resin collective is low;

(3) Improper design of anti-corrosion and anti-seepage lining;

(4) Influence of technological factors.

2. How to avoid water leakage in the FRP water tank in terms of installation

(1) There is no problem with the quality of the board and the rubber strip;

(2) There is no problem with the bolts;

(3) The installation technology is in place;

(4) Ensure the basic level of the water tank;

(5) Make sure that the water tank does not shake.

3. Solution for water leakage of FRP water tank

(1) If the cracks of the board are leaking and the seams are very small, you can use sealant or water-tight to repair the inside of the water tank. The method is: drain the water, bake it dry, and sprinkle the sealant or water-tight water on the leaking parts. That's it. The plexiglass water tank can be bonded with ordinary unsaturated resin. If it is a food-grade pure water tank, it is recommended to use food-grade 1629 resin to bond the inner seam, and it does not matter for industrial use.

(2) If there is water leakage at the joint between the plate and the plate, it means that the middle rubber strip is not clamped or the bolt is not tightened. The repair method is to tighten the bolt (tighten one end).

(3) If there is water leakage at the four corners and the plugging place, it means that the rubber strips are not in place or the plugging direction is misaligned. The repair method is to remove the plugging, put some rubber strips, and reinstall it.

(4) If it is winter, you have to see if the FRP water tank will leak due to freezing and cracking. The FRP water tank will not freeze under normal use, that is because: the water in the FRP water tank is used and renewed every day, and the FRP water tank is insulated, even if you run out of water in the water tank, Its water temperature is still higher than the added cold water, but there is another situation, that is, it is not used for a long time, the weather is very cold, and there is not much water in the water tank, so it may freeze, such a situation a bit less. But not without.

4. How to prevent leakage of FRP water tank

The way to prevent the leakage of FRP water tank can be from two aspects of design and process.

(1) Design aspects:

a. Resin varieties should be reasonably selected according to the storage medium during design.

b. Reasonably design the thickness of the inner lining of the storage tank, which should be greater than 2mm. The reinforcing materials of the inner lining layer are surface felt and chopped strand mat, the resin content in the surface mat is 90%, and the resin content of the chopped glass fiber mat layer should be greater than 70%.

c. Toughen the resin so that its elongation is equal to or greater than that of the glass fiber.

d. Adding an appropriate amount of coupling agent to the resin increases the density of the coupling agent on the interface between the glass fiber and the resin.

(2) In terms of technology:

a. The bonding seam should be strict and careful.

b. Improve the sense of responsibility of the operators and strictly implement the process regulations.

c. Metal embedded parts should be galvanized. In the process of process transfer, it is necessary to prevent secondary pollution.

d. During the production process, it is necessary to ensure the compactness between layers, and to eliminate air bubbles and cracks as much as possible.

e. Strictly manage the glue distribution. Generally, the glue should be mixed by a special person, and the match should not be too large at one time to ensure a uniform supply.

f. When manufacturing the inner lining layer, it is necessary to wait for the resin gel of the surface felt layer before laying the chopped glass fiber mat layer: it is also necessary to lay the structural layer after the resin gel in the chopped strand mat layer, so as to ensure the inner lining. resin content of the layer.

The above is the "cause of water leakage in the glass fiber reinforced plastic water tank and the solution". We must maintain it regularly when using the glass fiber reinforced plastic water tank, so that the service life can be longer. If you want to know more about the FRP water tank, please contact CANATURE HUAYU factory, a professional manufacturer of FRP water tank and Brine Tank, welcome to contact us to wholesale and customize the style you want.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba