Electric heating tape is a commonly used heating and insulation equipment, widely used in various fields. During the use of electric heat tracing, there may be situations where the heating efficiency cannot reach the desired effect. In order to improve its heat dissipation efficiency and ensure its long-term stable operation, some methods can be adopted to expand the heat dissipation area of the electric heating tape.

Models with larger heat dissipation areas are available. In this way, under the same working conditions, its heat dissipation effect will be better.

Electric heating cables with larger heat dissipation areas can be customized according to actual needs.

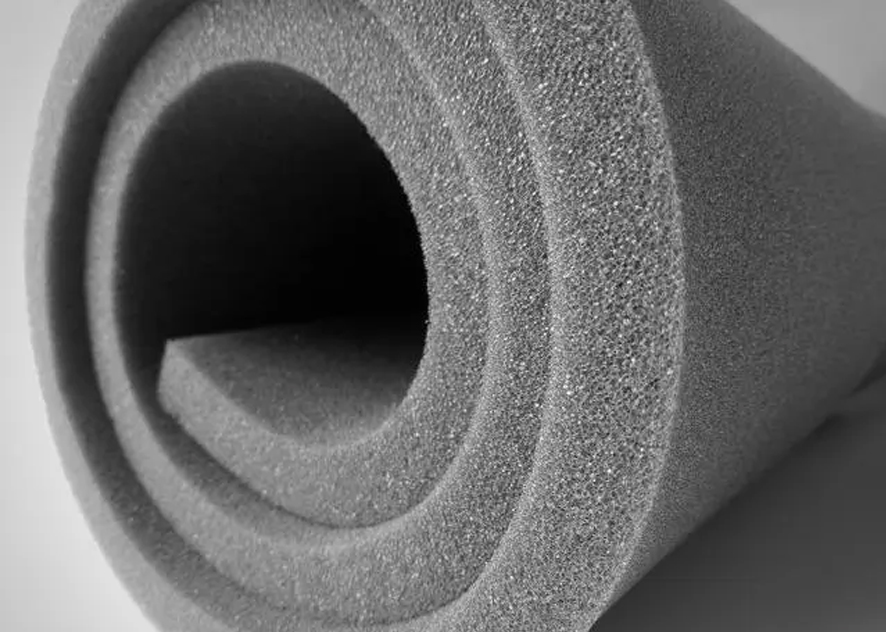

The heat dissipation area can be enlarged by changing the installation method of the electric heating cable. For example, the heating cable can be installed in a coil so that it fits closely with the heat dissipation surface, thereby improving the heat dissipation efficiency. In addition, multiple electric heating cables can be installed in parallel to increase the heat dissipation area.

For some specific application scenarios, the heat dissipation area of the heating cable can be enlarged by optimizing the operating parameters of the heating cable. For example, the operating temperature of the electric heating cable can be appropriately increased to increase the heat dissipation. At the same time, the power distribution of the heating cable can be adjusted to make it more uniform during the heating process and avoid hot spots.

According to actual needs, a suitable heat dissipation device can be selected to be used in conjunction with the electric heating tape to expand its heat dissipation area. For example, you can choose a radiator or cooling fan with a larger heat dissipation area, or add heat sinks to the surface of the electric heating tape.

Increase the number of heating pipes. When long-distance, large-diameter pipes are insulated and heated, the number of heating pipes can be increased based on the original electric heating belts, thereby increasing the total heat dissipation area and improving the heat dissipation effect.

Change insulation materials. On the basis of the original insulation materials, a layer of insulation materials with better thermal conductivity, such as asbestos, rock wool, etc., can be added to improve the insulation effect and indirectly improve the heat dissipation effect.

In short, expanding the heat dissipation area of electric heating tape requires comprehensive consideration of various factors. According to the actual situation, reasonable selection, installation and operation optimization can effectively improve the heat dissipation efficiency of electric heating tape and ensure its long-term stable operation.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba