This article will introduce in detail the construction process of electric heating of natural gas pipelines, including pre-installation preparation, installation process, and post-installation inspection and maintenance, etc., aiming to help readers understand and master the implementation method of this process.

Preparation before installation

1. Understand the various indicators, structures and installation methods of electric heating cable products to ensure that the products meet the design requirements.

2. Confirm that all process pipelines (vessels) have been constructed and have passed the water pressure (air tightness) inspection. The surface of the pipeline has been rust-free, anti-corrosion, dry and smooth, without burrs or dirt.

3. Conduct a visual inspection of the installed electric heating tape products to see if the device is damaged, deformed, cracked or otherwise abnormal, and whether the mechanical temperature control of the cable is on and off normally.

4. Understand the installation diagram of the electric heating cable system, and confirm the product specifications, variety quantity and installation position.

5. Confirm whether the insulation material is dry, if it is wet, do not keep it warm, so as not to affect the heating and heat preservation effect of the electric heating cable.

6. Prepare the electric heating cable installation manual so as to record the installation content at any time.

Installation process

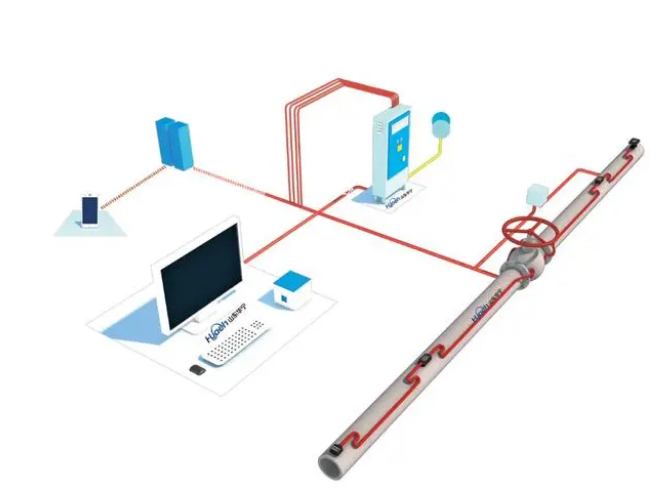

1. Use multiple parallel straight lines to wrap multiple electric heating tapes parallel to the outer wall of the pipe. It is generally suitable for long-distance, large-diameter pipes to ensure uniform heat dissipation.

2. During the installation process, be careful not to subject the electric heating tape to impact, pressure, or excessive bending to avoid damage.

3. During the installation process, keep your hands clean and do not touch the metal parts of the electric heating tape to avoid short circuits.

4. During the installation process, attention should be paid to ensuring that the electric heating tape and the pipe fit closely to avoid affecting the heat dissipation effect.

5. During the installation process, attention should be paid to ensuring that the wiring of the electric heating tape is correct and firm to avoid poor contact or short circuit.

Post-installation inspection and maintenance

1. Check whether the electric heating tape is installed completely, whether there is no damage to the appearance, and whether the wiring is correct.

2. Carry out a power-on test to check whether the electric heating tape is working properly and whether the heating is uniform.

3. During use, the heating condition of the electric heating tape should be checked regularly. If any abnormality is found, it should be dealt with in time.

4. During use, dust and dirt on the surface of the electric heating tape should be cleaned regularly to ensure the heat dissipation effect.

5. During use, care should be taken to avoid mechanical damage to the electric heating tape. If damage is found, it should be replaced in time.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba