Xiangtan Lufeng Machinery Co., Ltd

Main Products:rotary furance ,ingot casting machine , electrolysis machine system

Building B6, Accelerator Park, No. 18 Gaoxin Road, Xiangtan, Hunan Province, China

+86-17773276726

layla@xtlfjx.com

PRODUCT NAME :

equipment metal refining for mine and metallurgy lead liquid tank mixer

Lead pot mixer

Suitable for slowly rotating and stirring the lead solution in crucible type lead furnaces, pool type lead furnaces, reflective lead furnaces, lead solution pouring bags, and static boxes;

1. The equipment uses a crane to lift the disc cover and install it at the furnace mouth, which is simple and fast;

2. Adopting stainless steel shaft configuration with impeller rotation for high-power rapid mixing (the mixing shaft is provided by the buyer).

1. Rated power supply: 3-phase, 380V.

2. Rated frequency: 50Hz.

3. Rotor spindle turbine reducer motor: 18.5KW;

4. Rotary shaft speed: 0-250r/min (speed control motor+digital display speed control meter);

5. The diameter of the upper flange plate connecting the stainless steel mixing shaft is 90~100mm, and six 8mm circular holes are evenly distributed on the flange plate;

6. Set necessary indicator lights for the electronic control system: power supply, operation, emergency stop button, start/stop button, etc; Each button is clearly and securely labeled.

1. One hoisting mixer; 2. 1 mobile bracket (convenient for placing the hanging disc mixer when not in operation);

3. One electric control box; 4. One circuit diagram instruction manual.

PRODUCT PICTURES:

equipment metal refining for mine and metallurgy lead liquid tank mixer

equipment metal refining for mine and metallurgy lead liquid tank mixer

equipment metal refining for mine and metallurgy lead liquid tank mixer

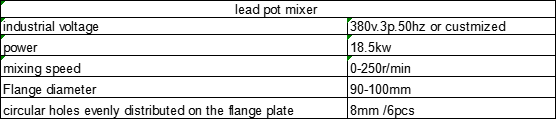

SPECIFICATIONS:

equipment metal refining for mine and metallurgy lead liquid tank mixer

Xiangtan Lufeng Machinery Co., Ltd. was established in 2010 and is located in the Industrial Park of Hunan Xiangtan High-tech Zone. Through more than 10 years of precipitation and development, Lufeng company has made many achievements in the design and manufacture of high-quality copper&lead&zinc smelting equipment.

Today, Lufeng has become one of the best manufacturers of high-quality smelting equipment in China and abroad, such as copper&lead smelting furnace, linear ingot casting machine, disc ingot casting machine, lead pot refining system, lead-acid battery crushing and sorting system, copper&lead&zinc electrolysis system, etc.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba