Dongguan Yuanyang Thermal Technology Co., Ltd

Main Products:

Factory Building, No. 6 Haizi North Road, Heng Shan Village, Shipai Town, Dongguan City Guangdong Province

+86-18676922995

bruce@venticool.cn

Product parameters of Factory Custom Copper Extrusion Heatsink with Heat Pipe

Material: CU 1100

Thickness:0.2mm

Diameter: Φ 8mm

Feature: High efficiency Heat conducting

Surface treatment: passivation

Heat conducting power: 80W

Product Technology of Factory Custom Copper Extrusion Heatsink with Heat Pipe

All electronic components, from microprocessors to high end power converters, generate heat and rejection of this heat is necessary for their optimum and reliable operation. As electronic design allows higher throughput in smaller packages, dissipating the heat load becomes a critical design factor. Many of today's electronic devices require cooling beyond the capability of standard metallic heat sinks. The heat pipe is meeting this need and is rapidly becoming a main stream thermal management tool. Heat pipes have been commercially available since the mid 1960's. Only in the past few years, however, has the electronics industry embraced heat pipes as reliable, cost effective solutions for high end cooling applications. So now here what we explain basic heat pipe operation, review key heat pipe design issues, and to discuss current heat pipe electronic cooling applications. A heat pipe is essentially a passive heat transfer device with an extremely high effective thermal conductivity. The two-phase heat transfer mechanism results in heat transfer

capabilities from one hundred to several thousand times that of an equivalent piece of copper.

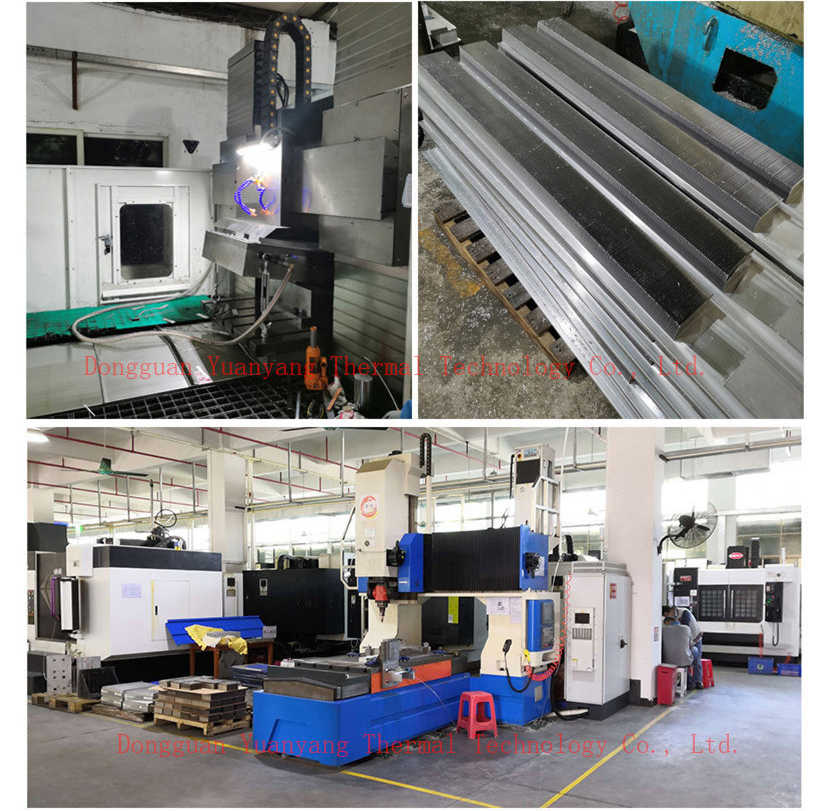

Our machines:

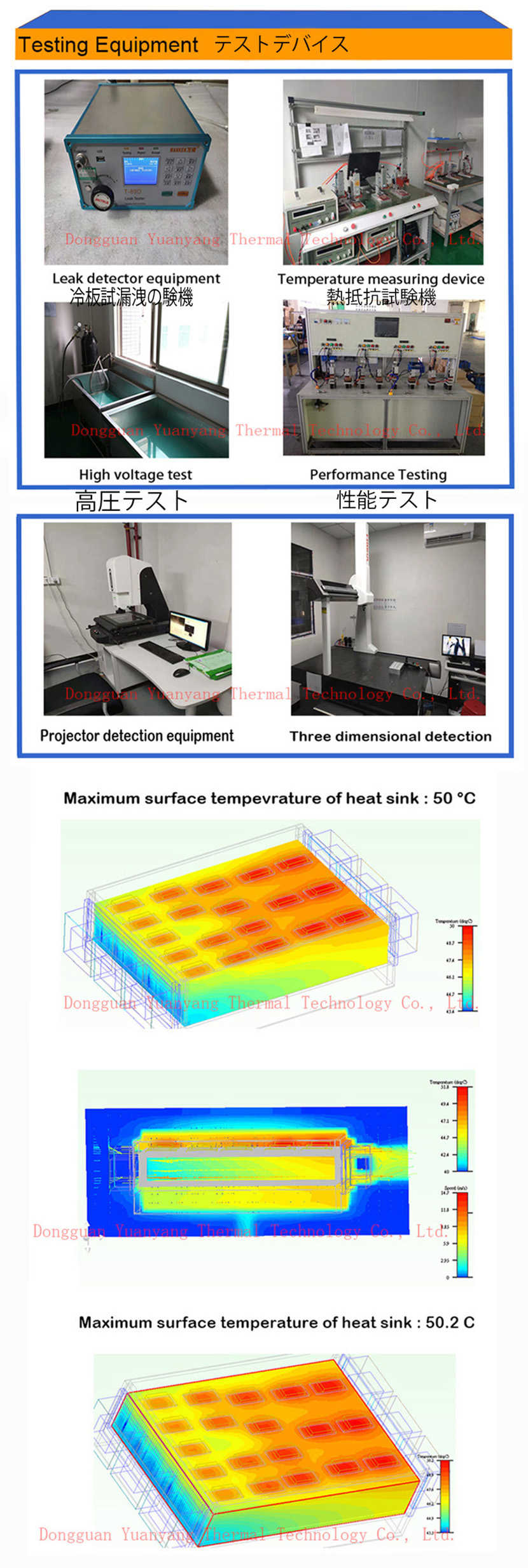

Our testing machines:

Our soldering assembly line:

Our team:

We as a team,move forward and backward together;

We have good services,high efficiency and great development;

We are market -sensitive and have strong will for the modern market.

Our Certificate

Our service:

1.Once received the inquiry will be quickly replied

2.Keep the product be qualified and price be reasonable and competitive.

3.Fastly arrange production and improve efficiency.Get the goods be finished on time.

4.We can advice the best transportation depends on the goods weight and cubic meter

5.Any questions with the goods we made, we will offer the best solution and technique support.

FAQ

1. Q:Are you trading in company or manufacturer?

A:We are the professional manufacturer of heat sink and water cooling plate that has much experiences and strong technique team,automatically and mechanized production

2. Q:Have you exported the goods before and to which regions?

A:60% goods in total has exported abroad,to Japan,India,British,Canada,America and Brazil.

3. Q:How many employees you have?

A:we have about 100 employees,including sales,purchase,engineering,QA,warehouse and production department.

4. Q:If I agree with the design,can you provide the samples we need?

A:Yes,we can.we surely will provide the samples to you for confirmation before mass production.Meanwhile the drawing we could provid if needed

5. Q:What packing you're using and can be assured safty?

A:Every goods are be packed with customized packing ways in normal cartons with tight proof fabric and wooden cartons for great protection, so it is safe during transportation.

6. Q:If we have any questions with products,can you provide the technique and solution?

A:Every products are fully checked before shipping, if there is problems you're facing,please feel free to let us know,we will offer best solution at once.

Dongguan Yuanyang Thermal Technology Co., Ltd was founded in 2014, located in high advanced industrial zone of Dongguan.

With 6 years of successful experience, we are certified high and new technology enterprises, focusing on research, development, production and sales of thermal management products, solution and one-stop service. We introduce 25 CNC machines, 10 stamping machines, 2 Friction welding machines and 4 Wire cutting machines, provide more quality and reliable thermal management solution products and one-stop service. The Thermal solutions from our from our factory has made great success for the Top 500 and 1000 enterprises, such as high cooling power cold plates, friction welding stir cooling block. For heat pipes, it has more than 100 automatic production and 60 bending machines . Monthly production can reach to 1 million pieces of heat pipes. We are committed to becoming the leader of thermal management in the field of new energy, production area reaches more than 10,000 square meters. We have certificate of strength:ISO9001:2015, ISO14001:2015, IATF16949 ,at the same time, obtained innovation in the exploration of new energy, and has more than 20 patented products. We look forward to your coming and exploring the new energy field together. And it’s always our goal that devote to make higher values for customers.

Product lines: heat sinks, heat pipes and water cooling plates.

Production capacity: 2000-2500 Tons per month.

Surface Treatment: Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc.

Deep Processing: CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba