Qingdao Haitongyuanda Special Instrument Co.,Ltd.

Main Products:

No.10, Huaan Road, Chengyang district Qingdao City, Shandong Province, China

+86-87605018

qdhaitongda@yeah.net

1. Product Introduction of Combination EP and Lubricity Tester Model EP-C

Frictional resistance to rotation of the drill string is called torque, and frictional resistance to hoisting and lowering the drill string is called drag. Many different materials have been used as drilling fluid additives to improve lubricity, thereby reducing friction. The lubricity, or drill string to bore hole wall drag, of drilling fluid is a property of special importance in drilling directional wells. An increase in friction between drill string and borehole is expected when drilling a hole off-vertical. Most of the wells drilled from fixed platforms offshore are completed in deviated holes. Desirable characteristics of a lubricant for this purpose, aside from the obvious requirement of performing well as a lubricant, are that it is non-toxic and bio-degradable, and does not form an oily slick on water. Since evaluation of the various lubricating materials in the various types and quality of drilling fluid cannot realistically be done on the drilling rig, a functional (drilling fluid lubricity) test was designed to simulate the torque and drag produced by a given drilling fluid downhole. The tester models or approximates the speed of rotation of the drill pipe and the pressure with which the pipe bears against the wall of the hole where the friction is generated.

Extreme pressure lubricants have been developed to increase the life of bit-bearings. Extreme pressure lubrication deals with metal surfaces in rubbing contact with each other at very high pressures (30,000 to 100,000 psi (206,820 to 689,400 kPa)). Lubrication for the metal surfaces is provided by a pressure resistant film that is produced as a result of the chemical reaction initiated by a high temperature generated from friction at the area of contact. The combination EP (Extreme Pressure) and Lubricity Tester is a high-quality instrument designed to measure the lubricating quality of drilling fluids, provide data to evaluate the type and quantity of lubricating additives that may be required, and predict wear rates of mechanical parts in known fluid systems.

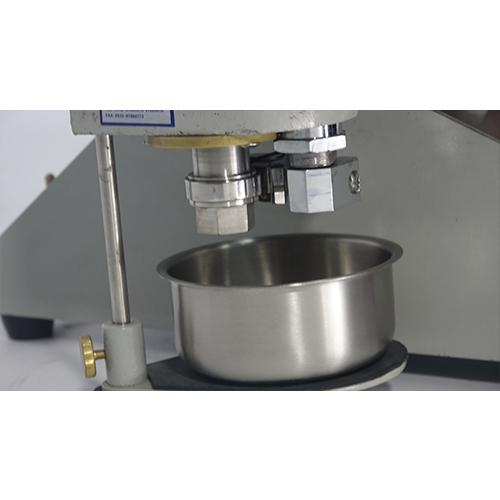

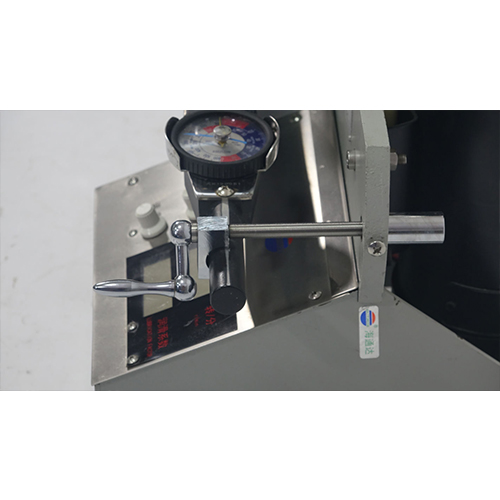

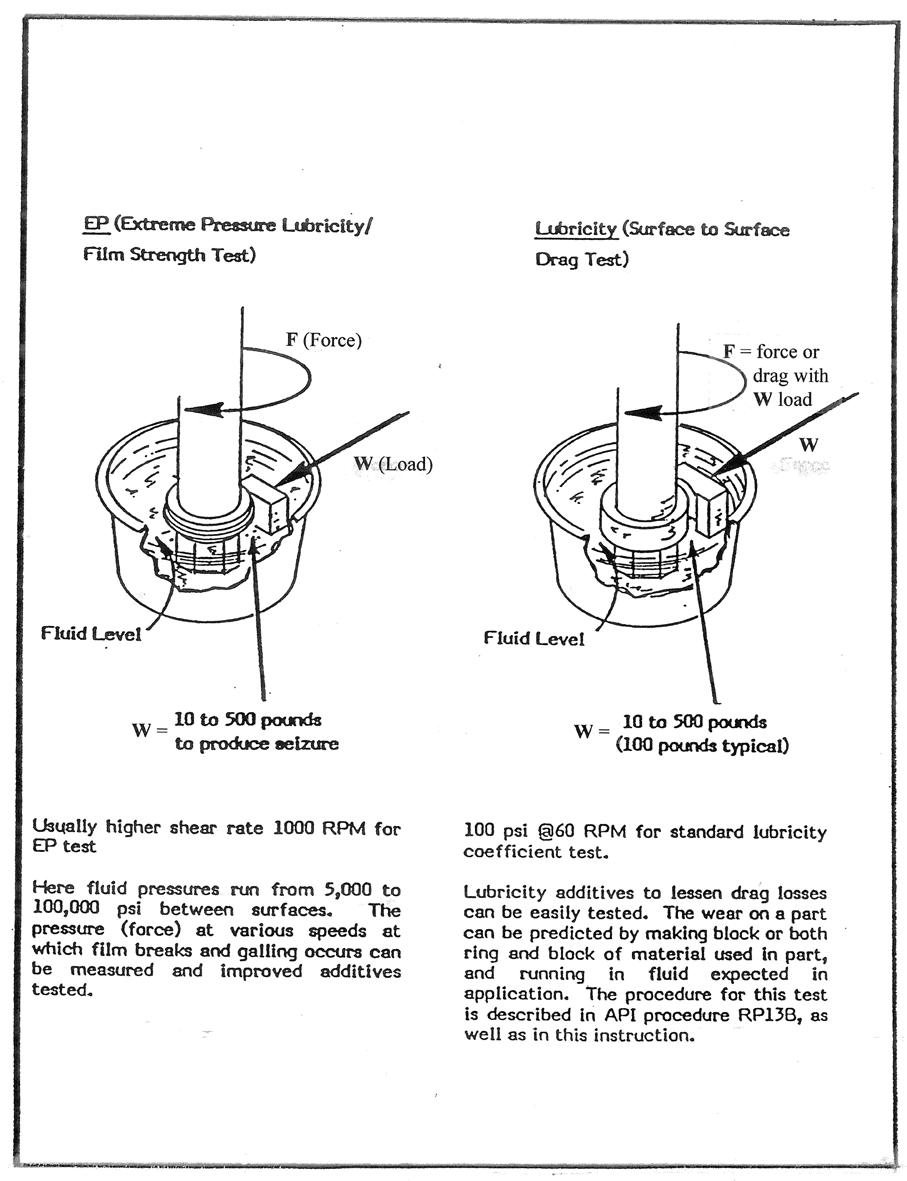

The EP tests (Fig. 1) are performed by applying a measured torque with a torque arm to a torque-sensitive, rotating bearing cup. This provides a means of testing lubrication under extreme pressure conditions and produces an indication of the film strength of the fluid being tested. The problem of reduction of friction between the drill string and the borehole requires a different simulation. The more common lubricity test (Fig. 1) measures fluid resistance (lubricating character) between two hardened steel moving surfaces at 100 pounds force (which translates into a 5,000 to 10,000 psi (34,470 to 68,940 kPa) pressure on the intermediate fluid film). During the lubricity test, a steel block is pressed against a rotating steel ring. Load in inch-pounds (in-lb) is read directly from the dial on the torque arm.

Measure of friction is a requirement for the determination of the film strength of a lubricant, for bit bearing wear, as is obtained in EP test and for the determination of torque or drag of the drill pipe as determined in the lubricity test. Friction is measured as the coefficient of friction (µ). The coefficient of friction (µ) between two solids is defined as F/W, where F denotes the frictional force and W is the load or force perpendicular to the surfaces. Thus, the coefficient of friction is independent of the apparent area of contact as long as this area is not so small as to break through the film; that is, with the same load W, the force to overcome friction will be the same for a small area as for a larger area. Applied to the Lubricity Tester, the load is the force with which the test block is pressed against the test ring through the torque arm. The force F required to slide the block and ring surfaces across each other at a given rate is measured by the power required to turn the test ring at a prescribed number of revolutions per minute. The coefficient of friction, µ = F/W. Refer to Figure 1.

Figure 1 - Comparison of EP and Lubricity Test

Figure 1 - Comparison of EP and Lubricity Test

2. Product Type Specification of Combination EP and Lubricity Tester Model EP-C

|

Model |

Name |

|

EP-C |

Combination EP and Lubricity Tester |

3. Product Technical Specification of Combination EP and Lubricity Tester Model EP-C

|

No. |

Technical Specification |

|

|

1 |

Power supply |

AC220V±10%,50HZ |

|

2 |

Power |

375W |

|

3 |

speed adjustable range |

30~400r/min Stepless speed regulation |

|

4 |

Lubrication coefficient |

33~37( Distilled water ) |

|

5 |

Net weight / Gross weight |

29.06kg/38.2kg |

|

6 |

Overall dimensions |

360×420×380mm |

|

7 |

Packing size |

670×476×480mm |

4. Product Detail of Combination EP and Lubricity Tester Model EP-C

High quality variable frequency motor and two-stage variable speed design principle not only make the motor play the best performance. And long service life, low noise. Extreme pressure lubricator is easy to operate, cheap, widely used in various oil fields, scientific research institutes, laboratories and other departments. It is the most ideal equipment for measuring the lubricity of drilling mud in the world.

Measurement procedure of reducing rate of drilling fluid friction coefficient:

1) Install the slider correctly (the wide surface is close to the axis, but not in contact with the axis), turn on the motor for 300r/min, idling for 15min, then adjust the speed to 70r/min, and turn off the motor after stability;

2) Add distilled water into the sample cup and run the motor idling for 5min (70 r/min);

3) Adjust the torque wrench 16.95N·m (the yellow needle indicates zero and the blue needle is 16.95N·m), adjust the speed to 60 r/min after pressurizing, loosen the torque wrench after stabilizing, and then adjust zero. Pressure to 16.95N·m for 5min, instrument reading should be within the range of 28 ~ 48 (±3);

4) Loosen the torsion wrench, turn off the motor, drain the distilled water, dry the test ring and test block surface, load the sample to be tested into the test cup, turn on the motor, pressure 16.95 N·m (60 r/min), turn for 5 minutes, read the instrument K value;

(5) each sample should be calibrated with distilled water once, distilled water friction coefficient of 28 ~ 48 (±3), should not continue to run in

5. Company Introduction of Combination EP and Lubricity Tester Model EP-C

China Haitongyuanda Special Instrument factory is a Multilink Low Pressure Filter Press Model SD3B supplier and manufacturer with full R&D, sales and service. Our company is committed to the R&D and manufacturing of drilling fluid analyzer, oil well cement tester, oilfield laboratory integrated engineering solutions and experimental instrument maintenance services. Over the past 40 years, with the care and support of oilfield users, experts from various industries and engineers and technicians, our products and technologies have been tested by the market making. Haitongda special analytical instruments have grown to world-famous brands. Our company has researched and developed testing instruments needed in unconventional oil and gas resources, deep water, natural gas hydrate and intelligent drilling, and successively produced a variety of new products, such as ultra-HTHP rheometer, drilling fluid online testing system and deep water low temperature drilling fluid testing system, which timely met the needs of technological progress in the drilling industry. At present, we are providing quality services and practical products to more than 3,000 customers in more than 20 countries and regions around the world.

6. FAQ

1): Are you a manufacturer or a trading company?

A1: We are manufacturer.

2): What is your main brand?

A2: Our brand is Haitongda, which is famous in China and other nation. Also we do OEM.

3): What are your business scope and product classification?

A3.Business scope. Mud analysis instrument, electronic products, special instrument, mold design and manufacturing; Instrument maintenance and sales, import and export of goods and technologies.

Product classification including drilling fluid analysis instrument oil ell cement testing instrument and field overall solution, including 22 small categories and over 120products.

4): What is your MOQ for the order?

A4: Testers per 1 set.

5): What is the warranty period of your instrument?

A5: One year.

6): Can l get better offer if our order can be bigger?

A6: Certainly. We will give you better prices based on the quantity for your order.

7): What certificate do you have for your instrument?

Q7: ISO, SGS and so on.

8): What is your lead time for our order?

A8: For new order: 3 weeks.

For stock order: 3 working days after T/T. Based on FOB Qingdao.

9): What is your advantage of your factory?

A9: We are the original oil ministry designated drilling fluid analysis equipment manufacturer in China, which was founded in 1968.

10): What is the process to become an agency?

A10: Please send us mail enquiry, then we will reply you as soon as possible.

Our company is committed to the R&D and manufacturing of drilling fluid analyzer, oil well cement tester, oilfield laboratory integrated engineering solutions and experimental instrument maintenance services. Over the past 40 years, with the care and support of oilfield users, experts from various industries and engineers and technicians, our products and technologies have been tested by the market making. Haitongda special analytical instruments have grown to world-famous brands. Our company has researched and developed on testing instruments needed in unconventional oil and gas resources, deep water, natural gas hydrate and intelligent drilling, and successively produced a various of new products, such as ultra-HTHP rheometer, drilling fluid online testing system and deep water low temperature drilling fluid testing system, which timely met the needs of technological progress in the drilling industry. At present, we are providing quality services and practical products to more than 3000 customers in more than 20 countries and regions around the world.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba