Union Profit (UP) Rapid Technologies Co., Ltd.

Main Products:

13 Building Qiaoshangwei, Songgang St. Shenzhen City, 518105 China.

+86-13479987346

info@up-rapid.com

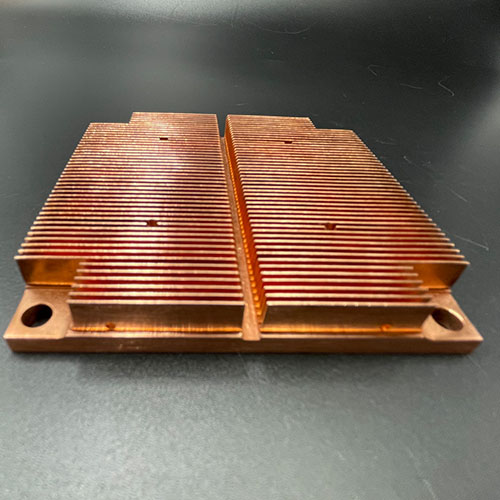

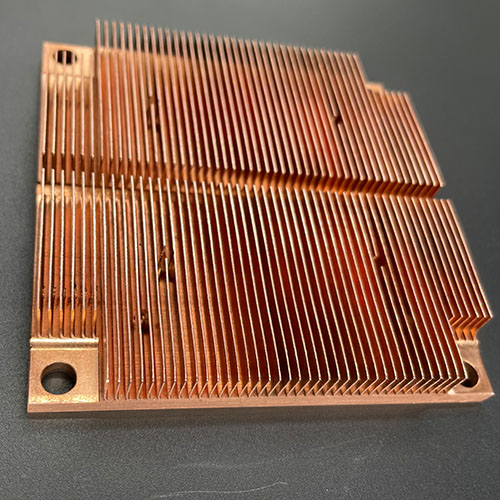

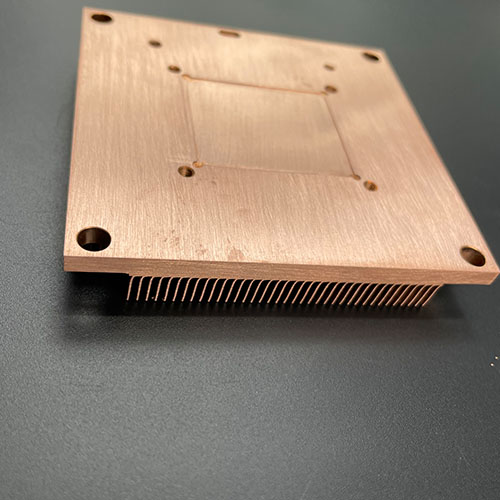

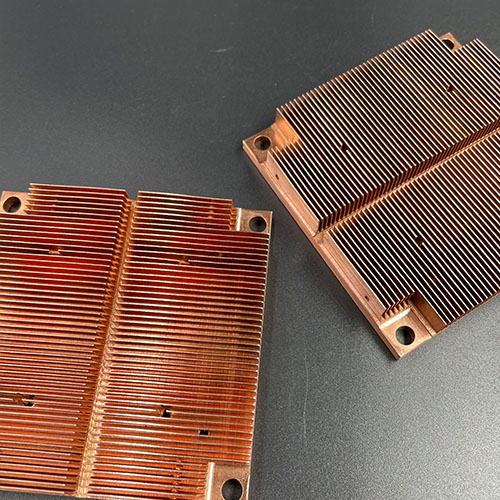

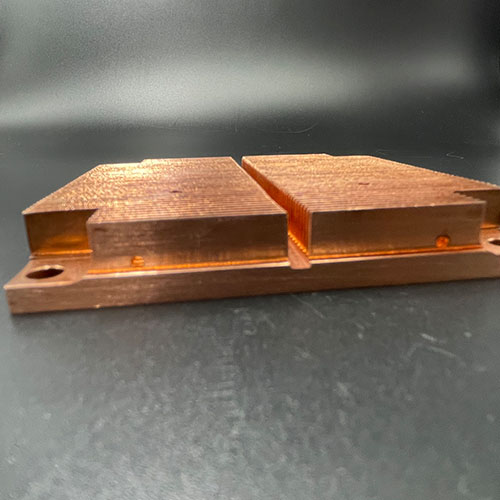

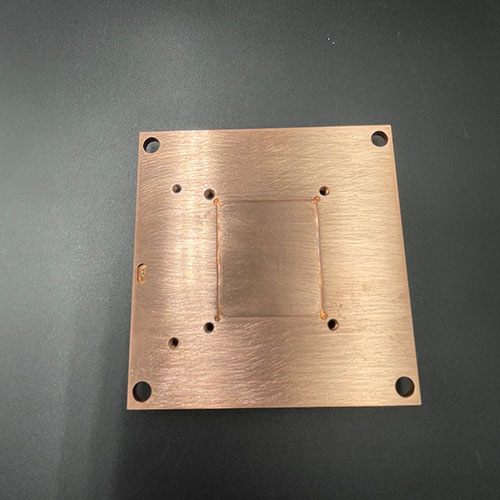

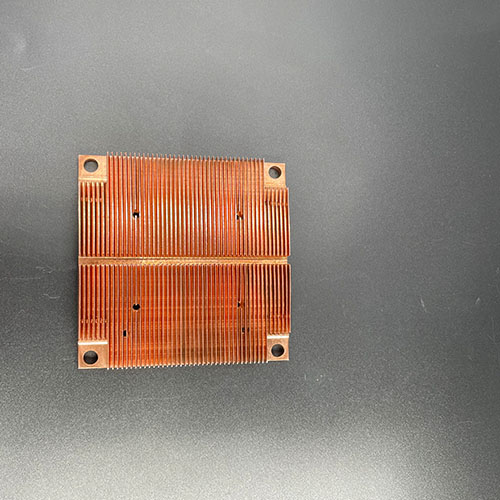

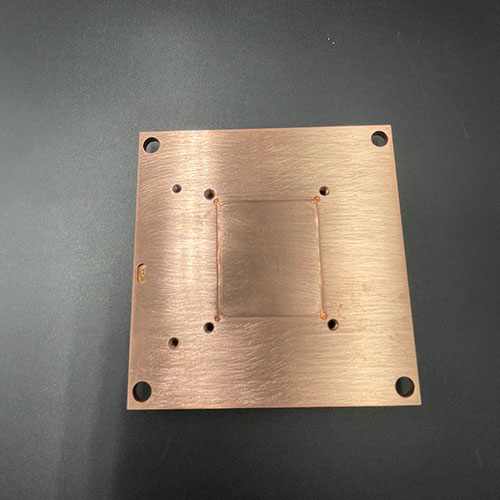

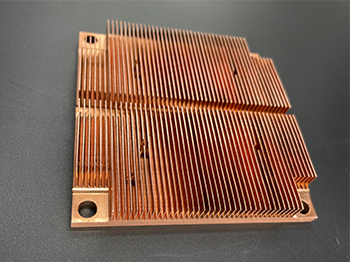

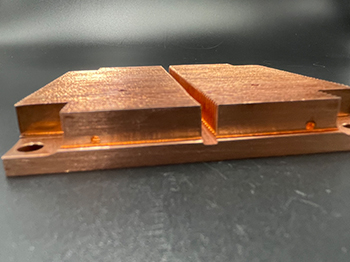

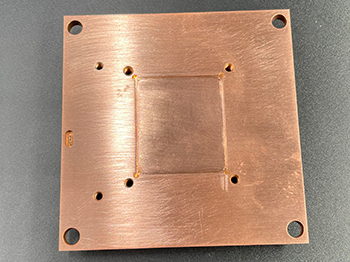

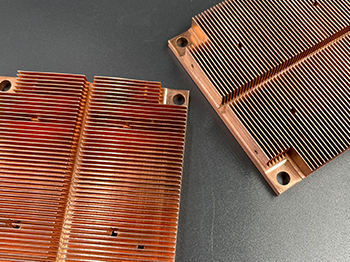

1. Quick Details of CNC Milling Copper Skived Fin Heatsink

| Place of Origin: | Guangdong, China | Model Number: | HJDJ403 |

| Type: | Custom | Material: | Al7075 |

| Finishing: | No | Finishing Color: | Copper-colored |

| Product name: | Car Steering Wheel | Size: | 110*110*35mm |

| Logo: | Laser Engraving accepted | MOQ: | 5pcs |

| Application: | Computer server, car, LED lighting, industrial computer etc. | Feature: | Skived Red |

| Methods: | CNC Milling | ||

| Payment: | T/T, Western Union, PayPal | Tolerance: | +/-0.01mm |

2. Supply Ability

Supplier Ability: 10000 Pieces per month CNC Milling Copper Skived Fin Heatsink

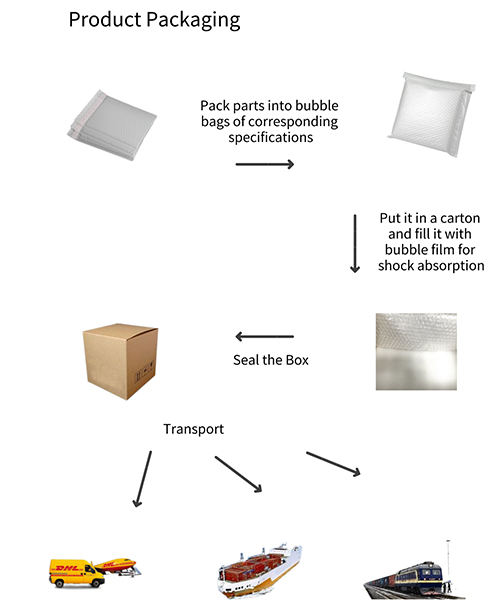

3. Packaging & Delivery:

Packaging Details 1pcs part in one pp bag+poly foam+carton

Port SHENZHEN

Lead Time

| Quantity(pcs) | 1-500 | >500 |

| Est. Time(days) | 25 | To be negotiated |

4. Product Description of CNC Milling Copper Skived Fin Heatsink

UP Rapid is a CNC fabrication company that provide custom machined car steering wheel. We machine this part with 5-axis CNC to ensure its machining tolerance is +/-0.01mm. Auto parts are very suitable for CNC machining, especially during product development.

5. Product Show for CNC Milling Copper Skived Fin Heatsink

6. CNC Milling Copper Skived Fin Heatsink

Our CNC milling process produces custom prototypes and end-use production parts. We use 3-axis milling, 4-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals. With machined production parts, you can also get more competitive pricing at higher quantities in addition to first article inspection (FAI) reporting, material certifications, and additional finishing options like anodizing and plating.

Our CNC milling service is commonly used for functional prototypes, jigs and Fixtures and production components in lower volumes.

| CNC Milling | Material | US/in. | Metric/mm |

| Max Dimensions |

|||

| 3axis | Metals and Plastics(Acetal) | 43.31in.*18.11in.*25.59in. | 1100mm*460mm*650mm |

| 4axis | Metals and Plastics(Acetal) | 15.75in.*7.87in.*7.87in. | 400mm*200mm*200mm |

| 5axis | Metals and Plastics(Acetal) | 11.81in.*11.81in.*3.94in. | 300mm*300mm*100mm |

| Min Dimensions | |||

| All | Metals and Plastics(Acetal) | 0.25in.*0.25in.*0.04in. | 6.35mm*6.35mm*1.02mm |

| Tolerance | +/-0.02mm | ||

| Text | Minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). | ||

7. Material Options for CNC Milling Copper Skived Fin Heatsink

Radiators of different materials are to meet different industrial production needs, so each has its own advantages and disadvantages. Generally, we process radiators of the following materials.

| Material | Tensile Strength Yield(MPA) | Fatigue Strength(MPA) | Elongation at Break(%) | Hardness(Brinell) | Density(g/cm³) | Applicable Methods |

| Copper C101 | 69~365 | 90 | 55 | 81 | 8.89~8.94 | Sheet Metal, CNC Milling |

| Copper C110 | 76 | 76 | 45 | 57 | 8.89 | Sheet Metal |

8. Packaging Delivery

9. Factory & Facility

(Factory Building)

(Factory Perspective)

CNC Milling①

CNC Milling②

CNC Milling③

Quality Inspection Room

10. FAQ

Why should I choose UP Rapid company to do my parts subjects?

UP Rapid is a prototyping company integrating industry and trade, which means that you directly contact the CNC Milling Copper Skived Fin Heatsink manufacturer. Our own factory provides parts to you through our industrial CNC machining, 3D printing, sheet metal processing, and injection mold services.

How do you maintain the confidentiality of client projects?

We sign an NDA (nondisclosure agreement) with the customer, and the customer directly provides the 3D CAD model service to the factory, which avoids the multi-directional circulation of drawings and guarantees the confidentiality.

What is the advantage of working with UP Rapid?

We have high-precision manufacturing equipment and testing equipment to ensure the qualified rate of parts.

What industries use UP Rapid services?

We serve industries like consumer product, electronics, telecommunication device,and precision instrument.

How many processing equipment do you have?

We have 20 3+2axis milling&turning machines, 6 lathes, 20 3D printers, 5 injecting machines and other measuring equipment.

How to ensure that customers have a satisfactory service?

Our services include process consultation, progress report during cooperation, and seven-day after-sales service after completion.

Do you provide first article of inspection (FAI) service to customers?

We offer FAIs on machined and molded parts.

About Us

Finding Inspiration in Every Turn

This is your About Page. This space is a great opportunity to give a full

background on who you are, what you do and what your website has to offer.

Double click on the text box to start editing your content and make sure to add

all the relevant details you want site visitors to know.

Our Story

Every website has a story, and your visitors want to hear yours. This space is a great opportunity to give a full background on who you are, what your team does, and what your site has to offer. Double click on the text box to start editing your content and make sure to add all the relevant details you want site visitors to know.

If you’re a business, talk about how you started and share your professional journey. Explain your core values, your commitment to customers, and how you stand out from the crowd. Add a photo, gallery, or video for even more engagement.

Meet The Team

|

|

|

|

Don Francis Founder & CEO |

Ashley Jones Tech Lead |

Tess Brown Office Manager |

|

|

|

|

Lisa Rose Product Manager |

Kevin Nye HR Lead |

Alex Young Customer Support Lead |

Our Clients

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba